Best quality Copper Foil Thickness - Reverse Treated Copper Foil – JM

Best quality Copper Foil Thickness - Reverse Treated Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

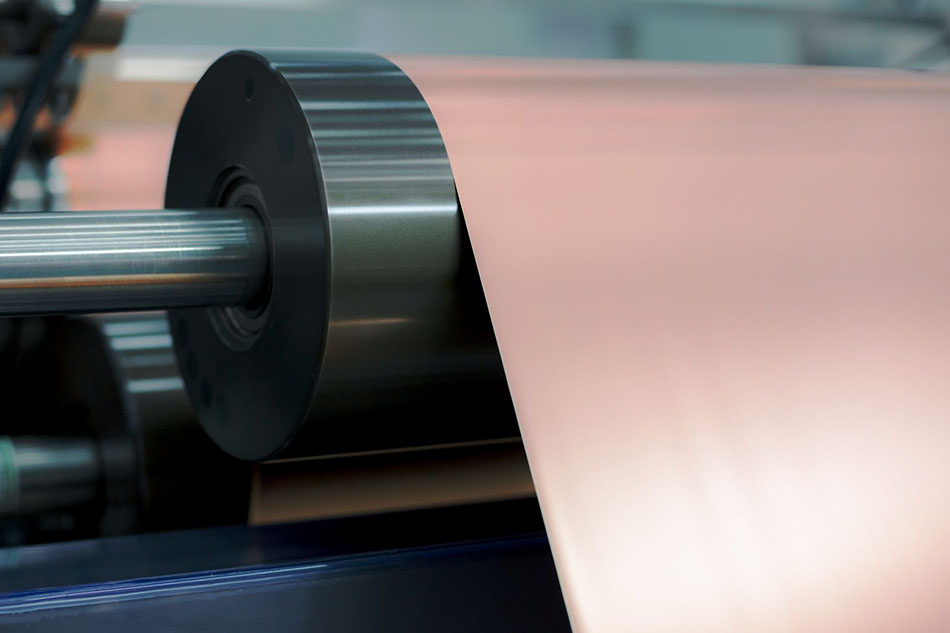

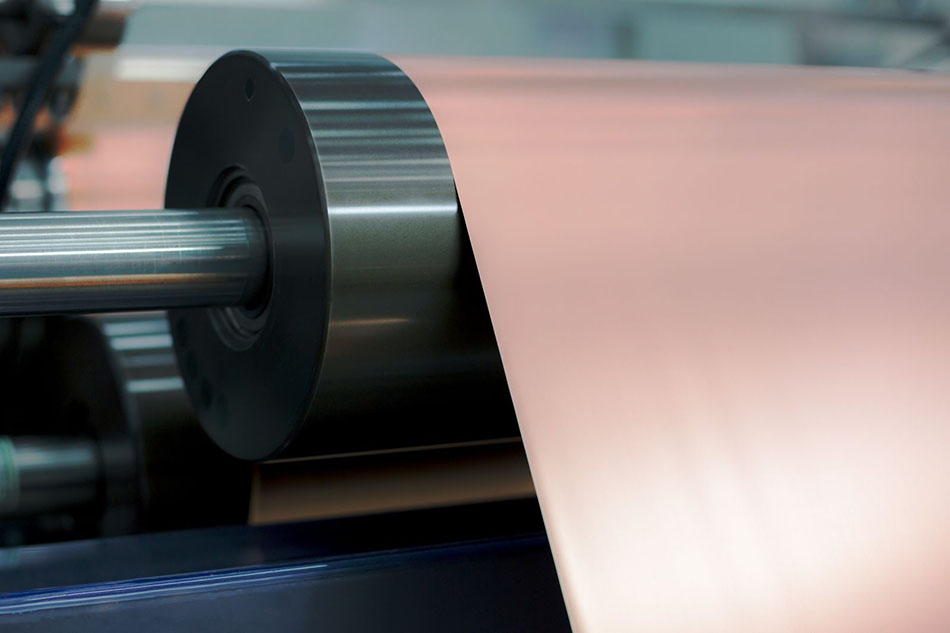

● Reverse treated copper foil

● Ultra-low roughness

● Excellent etchability

● The treated foil is pink

Application

● Server/switch/storage

● PPO/PPE

● Mid-low/low/ultra-low loss

Originate from the strict management and control of electrolytic copper production procedure.

JIMA Copper adopts advanced fabrication workmanship and management concept to exercise strict and scientific management for production of copper foil. in light of the need in links such as manufacturing and inspection of copper foil, this company builds 100000-level dustless workshop to ensure production of high performance and high quality copper foils products.

Typical Properties of Reverse Treated Copper Foil for Server/switch/storage

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

2.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.8 |

≥1.0 |

≥1.0 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥4.6 |

≥5.7 |

≥5.7 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

40 |

||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Best quality Copper Foil Thickness - Reverse Treated Copper Foil – JM , The product will supply to all over the world, such as: Berlin, Macedonia, California, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.