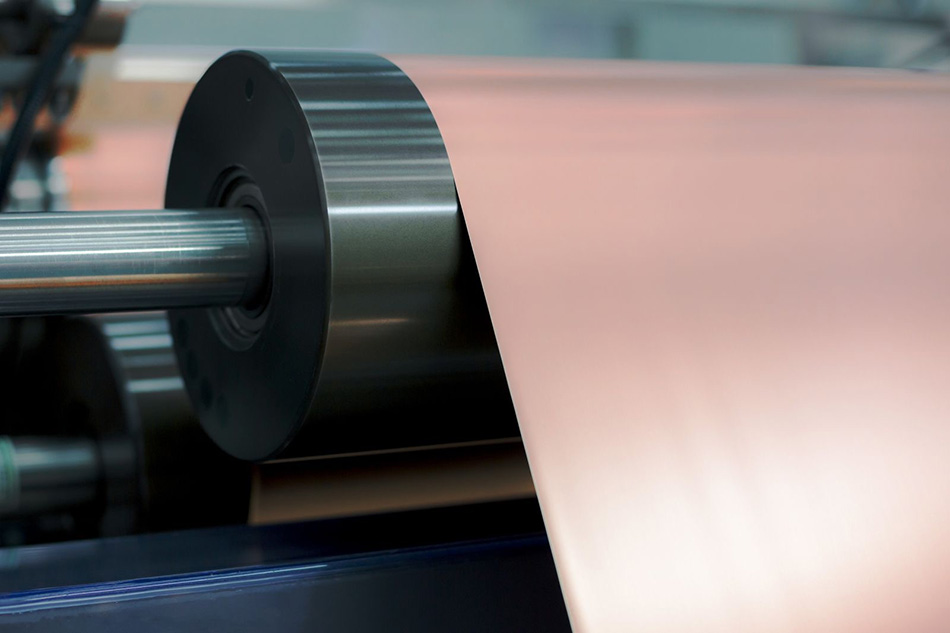

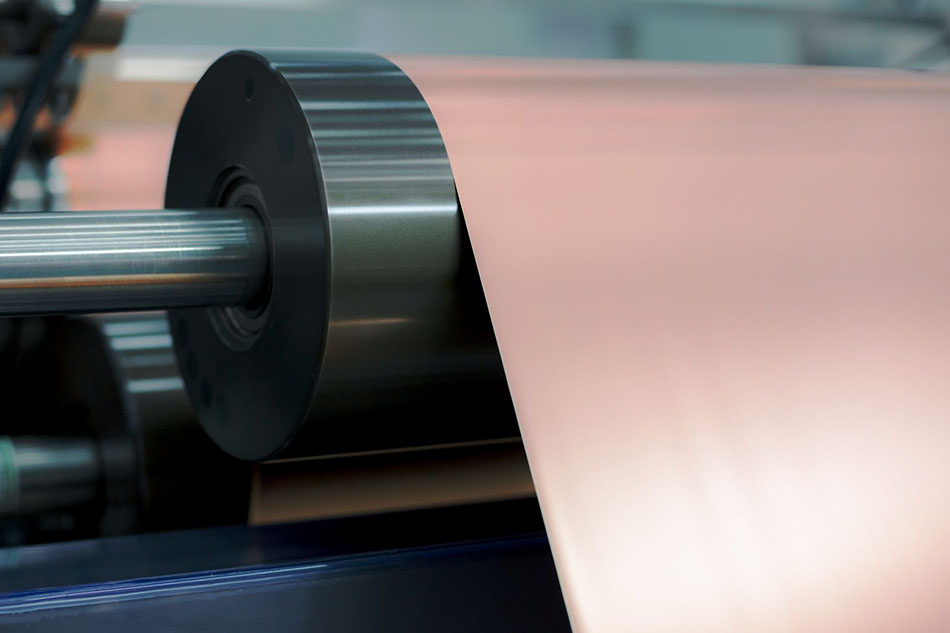

Bottom price Copper Foils For Led - Low Coarsening Reverse Treated Copper Foil – JM

Bottom price Copper Foils For Led - Low Coarsening Reverse Treated Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, we can do cutting as size requirement

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Lead time: 15-30days

● Term: FOB, CIF…

● Payment item: 50%T/T deposit, balance pay before shipping.

Features

● Reverse treated copper foil

● Low profile, with high peel strength

● The treated foil is pink

● As reverse-treated copper foil, this product has better etchability performance. It can effectively shorten the production process, achieve higher speed and fast micro-etching, and improve the conformance rate of PCBs.

Application

● High frequency, Ultra -high frequency, applying to PPE board

● Fine circuit pattern

● It is mainly applied in multilayered boards and high-frequency boards.

Typical Properties of Low Coarsening Reverse Treated Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

3.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.2 |

≥1.4 |

≥1.8 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.7 |

≥7.4 |

≥8.0 |

≥10.2 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

30 |

||||||

Standard Width,1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Electrolytic copper foil Image

Product detail pictures:

Related Product Guide:

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Bottom price Copper Foils For Led - Low Coarsening Reverse Treated Copper Foil – JM , The product will supply to all over the world, such as: Germany, Sacramento, Lesotho, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.