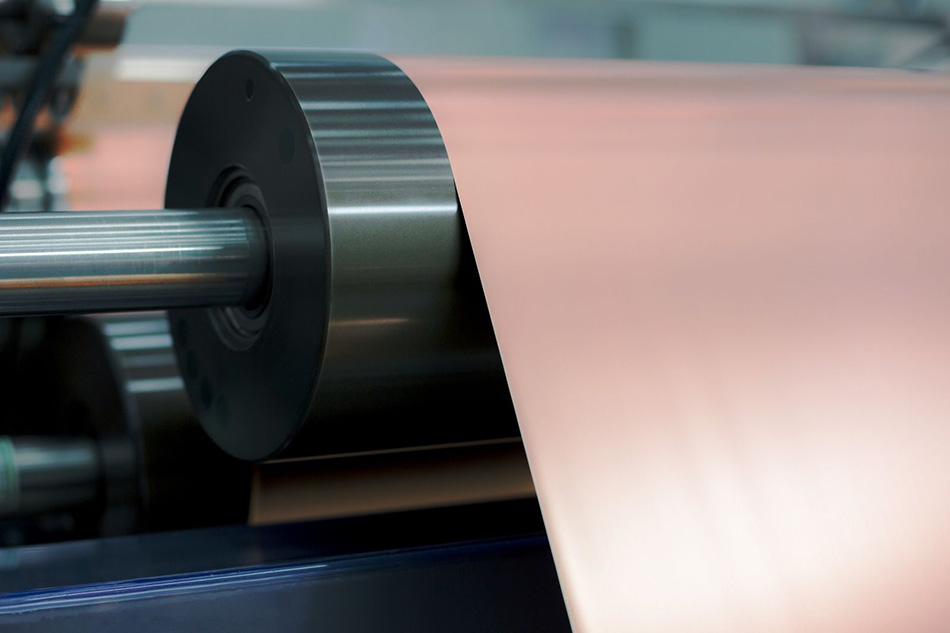

China New Product Teflon Laminate Copper Foil Pcb - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM

China New Product Teflon Laminate Copper Foil Pcb - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM Detail:

The raw foil, which has a glossy surface with ultra low roughness on both sides, is treated with JIMA’s proprietary micro-roughening process to achieve high anchoring performance and also ultra low roughness. It offers high performance in a wide range of fields, from rigid printed circuit boards that prioritize transmission properties and fabrication of fine pattern to flexible printed circuits that prioritize transparency.

Detail

● ID: 76 mm, 152 mm

● Roll Length/Outer diameter/Inner diameter: as request

● Core length: as request

● Core material: Paper and ABS plastic & Customize

● Sample can be supply

● Inner Package: can supply Vacuum packaging if need

Features

● Low profile for FCCL

● Grain structure of copper foil leads to high flexibility

● Excellent etching performance

● The treated foil is red or black

● Low profile enables to make fine circuit pattern

Typical application

● Casting and lamination type FCCL

● Fine pattern FPC&PWB

● Chip on flex for LED

● For FPC or Inner layer

● For a wide range of applications, from circuit boards to optics.

Typical properties of Matte Side Treatment Low Profile Copper Foil

| Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

10 |

12 |

16 |

25 |

35 |

IPC-4562A |

|

|

Area Weight |

g/m² |

98±4 |

107±4 |

153± 5 |

228± 8 |

285±10 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥4 |

≥4.6 |

≥5.7 |

≥6.3 |

≥6.9 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

60 |

||||||

Standard Width: 520mm 1040mm 1100mm, Max.1300mm May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for China New Product Teflon Laminate Copper Foil Pcb - Matte Side Treatment Very Low Profile Copper in Black/red (VLP-S-B/R) – JM , The product will supply to all over the world, such as: Chile, Swaziland, Iceland, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!