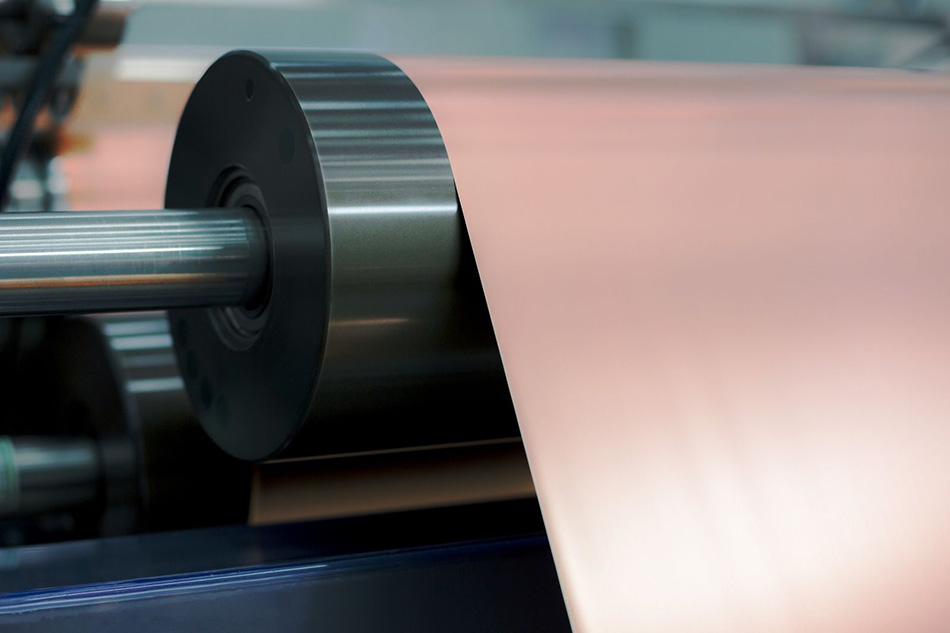

Electric Vehicles Li-ion Battery Double Side Shiny Copper Foil

Double-sided polished electrolytic copper foil is characterized by a symmetrical structure of two sides, metal density close to the theoretical density of copper, very low profile of the surface, excellent elongation and tensile strength, and so forth. As the cathode collector for lithium batteries, it has excellent cold/thermal resistance and can significantly extend the battery longevity. It can be widely applied in batteries for new-energy vehicles, the 3C industry represented by smart phones, notebook computers, and the ESS storage system, and space.

● Thickness: 4.5um 5um 6um 8um 9um 10um 12um

● Width: can be cutting as size request.

● Wooden box package, Inner Package: can supply Vacuum packaging if need

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Roll Length/Outer diameter/Inner diameter: as request

● Core length: as request

● Core material: Paper and ABS plastic & Customize

● Glossy both side superior rupture endurance

● Stable properties suitable for high capacity rechargeable battery

● Eco-friendly products and processes

● Excellent uniformity

● Excellent infiltration

● Electric Vehicles

● Li-ion Battery (LiB)

● Notebook PC

● Mobile phone

● Capacitor

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

6 |

8 |

9 |

10 |

12 |

IPC-4562A |

|

|

Area Weight |

g/m² |

54±2 |

70-75 |

85-90 |

95-100 |

105-110 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.9 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

≤3。0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥294 |

≥294 |

≥294 |

≥294 |

≥294 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥196 |

≥196 |

≥196 |

≥196 |

≥196 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥5 |

≥5 |

≥5 |

≥5 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥3 |

≥3 |

≥3 |

≥3 |

≥3 |

|||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

90 |

|

||||

|

R.T.(160°C) |

|

15 |

|

|||||