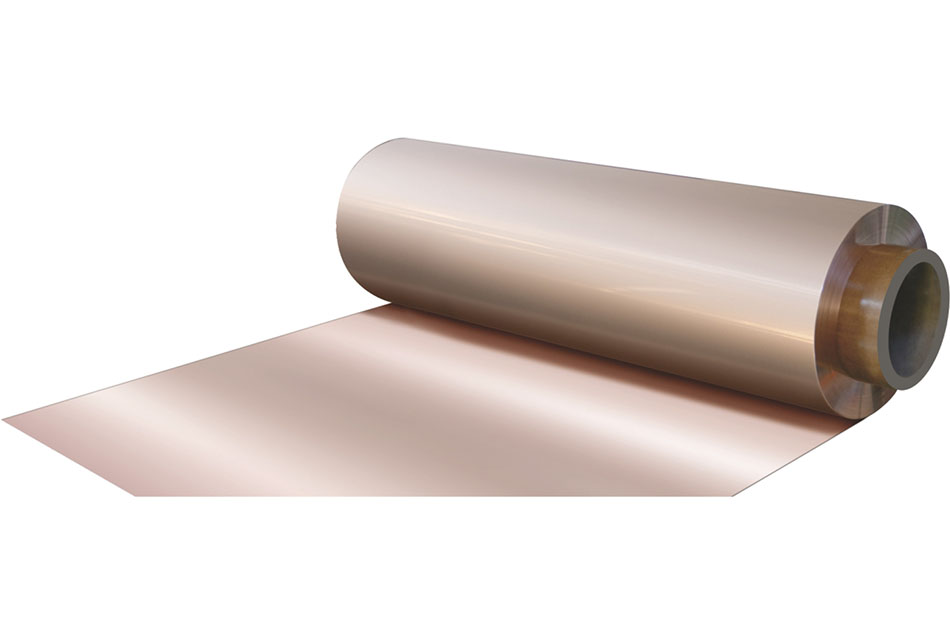

factory Outlets for Polished Copper Foil - 5G Electrolytic Copper Foil – JM

factory Outlets for Polished Copper Foil - 5G Electrolytic Copper Foil – JM Detail:

Specification

● Thickness: 12um 18um 35um

● Width: 300-1300mm. stadnard width 1290mm, can be cutting as size requirement

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Delivery: 10-20days

● Slitting Working Procedure: Conduct slitting, classification, inspection and package according to requirement for quality, width and weight of copper foils of customers.

Features

● Ultra-low profile, with high peel

● Strength and good etchability

● Hyper low coarsening technology

Application

● 5G High frequency board

● LCP/MPI/MTPI

Typical Properties of 5G Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||

|

Foil Designation |

|

T |

H |

1 |

IPC-4562A |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||

|

Roughness |

Shiny side (Ra) |

um |

≤0.43 |

IPC-TM-650 2.2.17 |

|||

|

Matte side(Rz) |

um |

1.0 |

optical method |

||||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥300 |

IPC-TM-650 2.4.18 |

|||

|

H.T.(180°C) |

≥180 |

||||||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥6 |

≥6 |

≥6 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.6 |

≥0.6 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥3.4 |

≥3.4 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

|||

|

H.T.(200°C) |

Minutes |

40 |

|||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for factory Outlets for Polished Copper Foil - 5G Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Armenia, Bolivia, United States, At present our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any products , please contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!