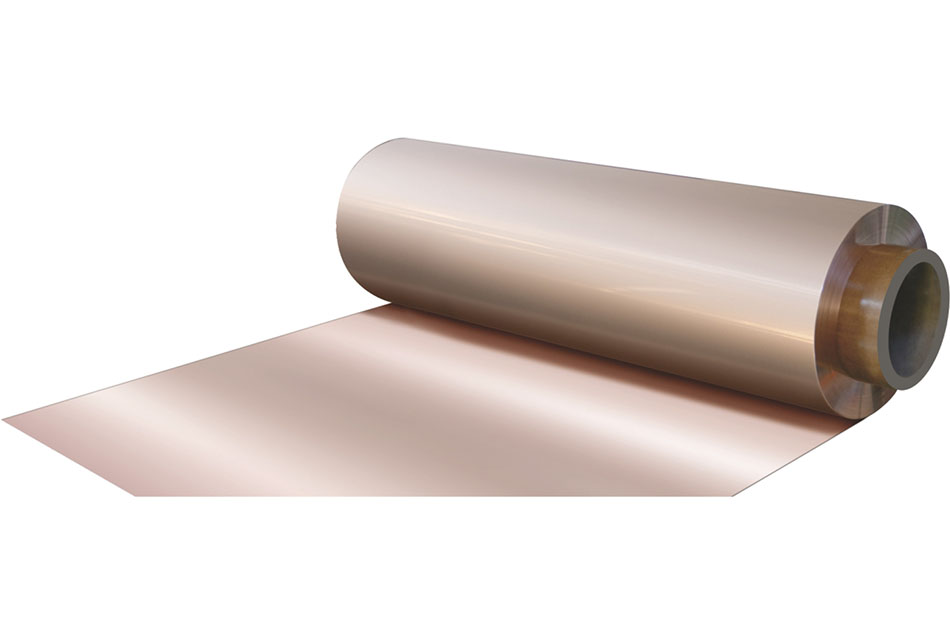

Factory source 1 Micron Copper Foil - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM

Factory source 1 Micron Copper Foil - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM Detail:

Detail

● Thickness: 10um 12um 18um 25um 35um

● Standard Width: 520mm1040mm 1100mm, Max.1300mm; can be cutting as per size request.

● Wooden box package

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

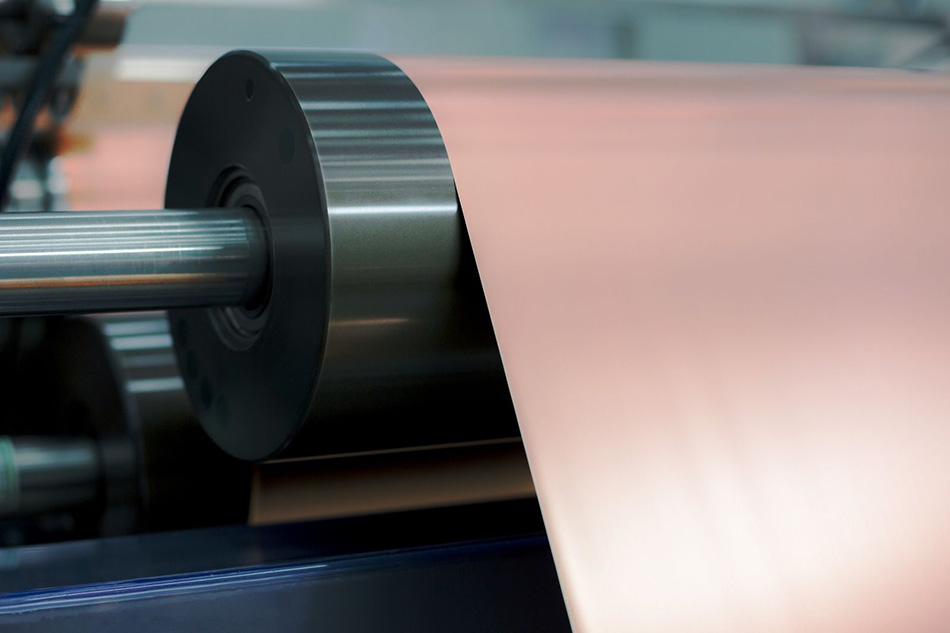

By increasing the density of the roughening treatment particles compared to previous products, this ultra low roughness copper foil boasts stronger adhesion to various substrates without increasing roughness. In addition to adhesion strength, it also offers various other features that enhance functionality and directly improve board reliability, such as long-term heat resistance and chemical resistance.

● Low profile for FCCL

● Grain structure of copper foil leads to high flexibility

● Excellent etching performance

● The treated foil is red or black

● Low profile enables to make fine circuit pattern

Typical application

● Casting and lamination type FCCL

● Fine pattern FPC&PWB

● Chip on flex for LED

● For FPC or Inner layer

● Despite the low roughness, this foil offers high adhesion strength, heat resistance, and high chemical resistance for use in a wide variety of application

Typical properties of Matte Side Treatment Low Profile Copper Foil

| Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

10 |

12 |

16 |

25 |

35 |

IPC-4562A |

|

|

Area Weight |

g/m² |

98±4 |

107±4 |

153± 5 |

228± 8 |

285±10 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥4 |

≥4.6 |

≥5.7 |

≥6.3 |

≥6.9 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

60 |

||||||

Standard Width: 520mm1040mm 1100mm, Max.1300mm May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Factory source 1 Micron Copper Foil - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM , The product will supply to all over the world, such as: Rio de Janeiro, Thailand, Hanover, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.