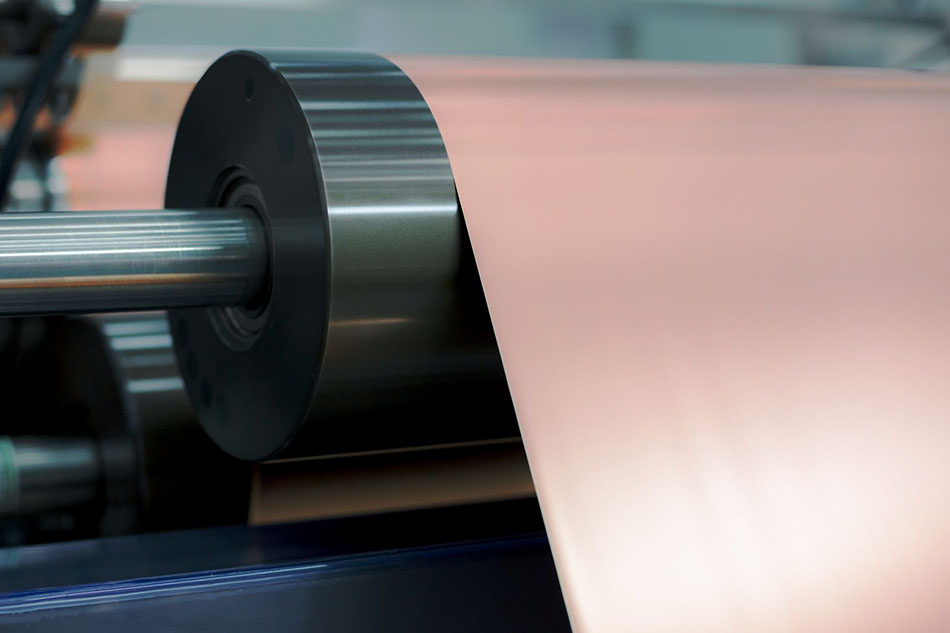

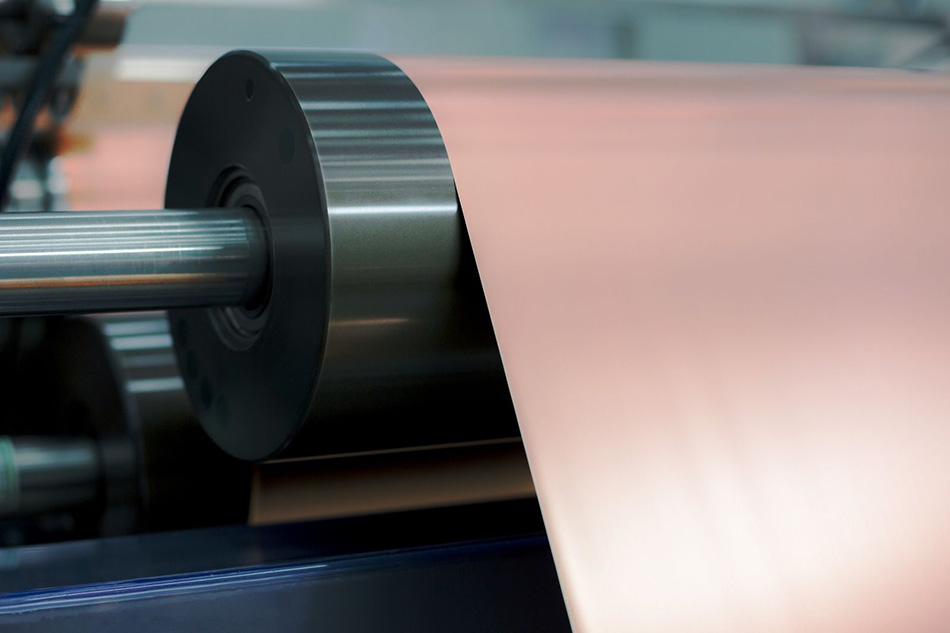

Factory Supply C11000 Copper Foil - HTE High Temperature Elongation Copper Foil – JM

Factory Supply C11000 Copper Foil - HTE High Temperature Elongation Copper Foil – JM Detail:

Detail

● Thickness: 12um 15um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● The quality is based on the GB/T5230-1995 and IPC-4562standard

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

The company has developed fine-grain and high-strength copper foil of low surface roughness and high-temperature ductibility performance. This foil features evenly fine grains and high extensibility and can prevent fissures caused by thermal stress, thus suitable for the internal and external layers of a multilayered board. With a low level of surface roughness and excellent etchability, it is applicable for high density and thinness. With excellent tensile strength, it helps to improve flexibility and is mainly applied in the multilayer PCB as well as the flex plate. With excellent resilience and toughness, it is not easily torn on the edge or fold, greatly improving the product conformance rate.

● The treated foil in grey or red

● High peel strength

● Good etchability

● Excellent corrosion resistance

● Anti foil cracking by high elongation at elevated temperature

● High elongation after treated with high temperature or annealing .

● High THE property.

● Effective in the prevention of cracking plate.

Application

● Polyimide board

● Epoxy board

● CEM-3, FR-4, FR-5, Hydrocarbon substrate

● Multilayer board

● High Tg, lead-free and halogen-free, Middle Tg

● Positive temperature coefficient resistance

Typical properties of High Temperature Elongation Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

|

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤6 |

≤8 |

≤10 |

≤15 |

≤20 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥207 |

≥276 |

≥276 |

≥276 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥103 |

≥103 |

≥138 |

≥138 |

≥138 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||

|

Resistivity |

Ω.g/m² |

≤0.17 |

≤0.166 |

≤0.16 |

≤0.162 |

≤0.162 |

IPC-TM-650 2.5.14 |

|

|

Peel Strength(FR-4) |

N/mm |

≥0.9 |

≥1.1 |

≥1.4 |

≥2.0 |

≥2.0 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥5.1 |

≥6.3 |

≥8.0 |

≥11.4 |

≥11.4 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

40 |

|

|||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

We test the peel strength with FR-4(Tg140) prepreg, please reconfirm with your pp.

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Factory Supply C11000 Copper Foil - HTE High Temperature Elongation Copper Foil – JM , The product will supply to all over the world, such as: America, Amman, Holland, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!