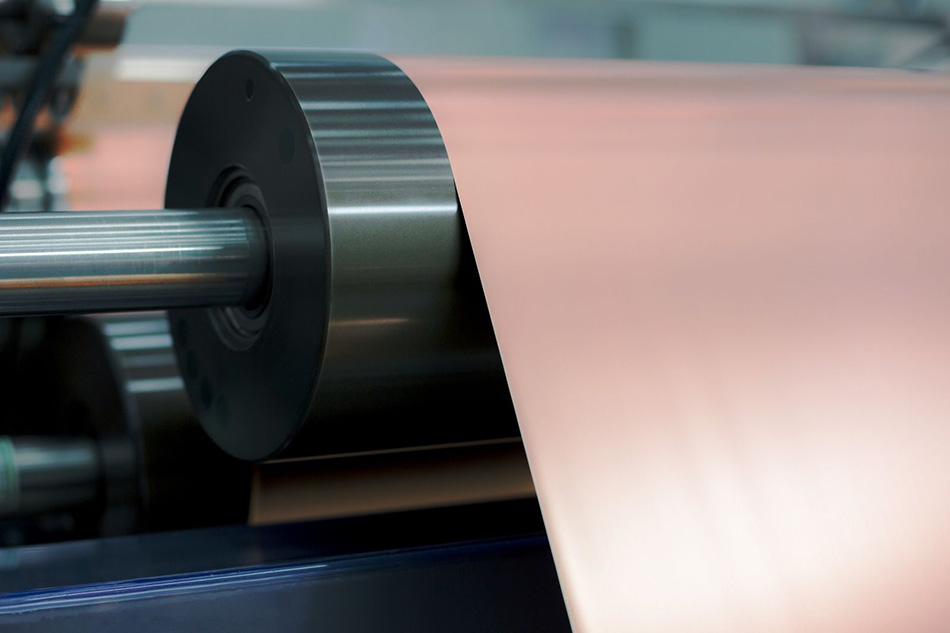

Factory wholesale Copper Foil Etching - STD Standard Copper Foil – JM

Factory wholesale Copper Foil Etching - STD Standard Copper Foil – JM Detail:

The STD series is an IPC grade 1 copper foil intended for use as the outer layer of rigid boards. It is available in thicknesses ranging from a minimum 12 µm to a maximum ED copper foil thickness of 140 µm. This is the only ED copper foil available in the 105 µm and 140 µm thicknesses, making it ideal for boards designed as heat sinks or to conduct large electrical currents.

Features

● The treated foil in grey or red

● High peel strength

● Good etch ability

● Excellent adhesions to etching resist

● Excellent corrosion resistance

Typical application

● Phenolic

● Epoxy board

● CEM-1, CEM-3

● FR-4, FR-3

● This is our standard ED copper foil product with the longest history of use as an outer layer for rigid boards.

Surface quality

● 0 splices per coil

● Foil to have uniform colour, cleanliness and flatness

● No obvious pitting, pin holes or corrosion

● No surface defects such as creases, spots or lines

● Foil must be oil free and have no visible oil spots

Typical properties of High Temperature Elongation Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

|||||||

|

Nominal thickness |

Um |

12 |

18 |

25 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

228±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12.2 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

IPC-TM-650 2.3.17 |

|

|

Matte side(Rz) |

um |

≤6 |

≤8 |

≤10 |

≤10 |

≤15 |

≤20 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥150 |

≥220 |

≥235 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥3 |

≥3 |

≥4 |

≥4 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

Resistivity |

Ω.g/m² |

≤0.17 |

≤0.166 |

≤0.162 |

≤0.16 2 |

≤0.162 |

≤0.162 |

IPC-TM-650 2.5.14 |

||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.3 |

≥1.6 |

≥1.6 |

≥2.1 |

≥2.1 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.1 |

≥6.3 |

≥8.0 |

≥11.4 |

≥11.4 |

≥11.4 |

||||

|

Pinholes & porosity |

Number |

|

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

|

|

180 |

|

|||||

|

R.T.(200°C) |

|

|

60 |

|||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Factory wholesale Copper Foil Etching - STD Standard Copper Foil – JM , The product will supply to all over the world, such as: Japan, Belarus, Armenia, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

We have been looking for a professional and responsible supplier, and now we find it.