Good quality Copper Foil Rf Shielding - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM

Good quality Copper Foil Rf Shielding - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

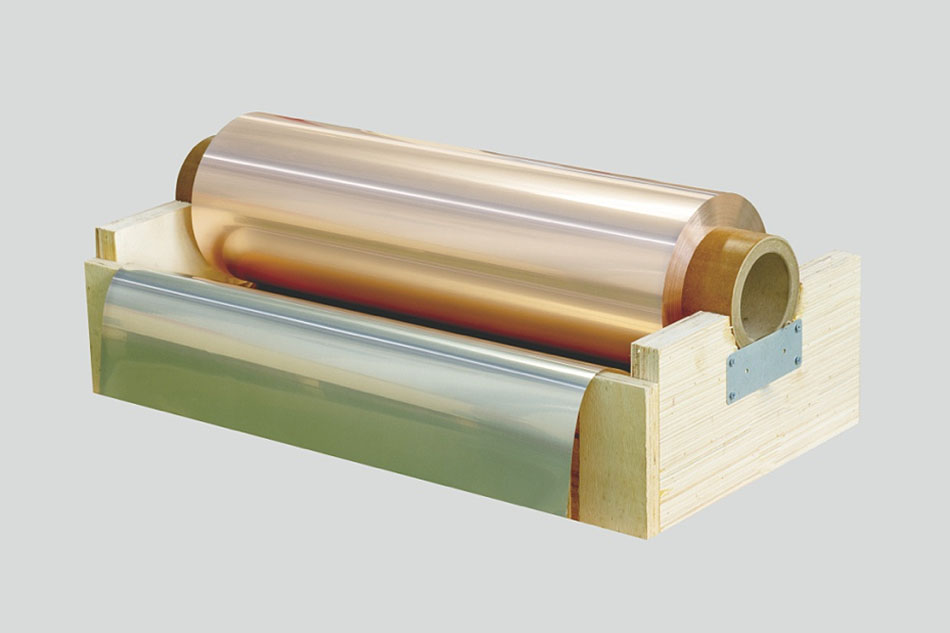

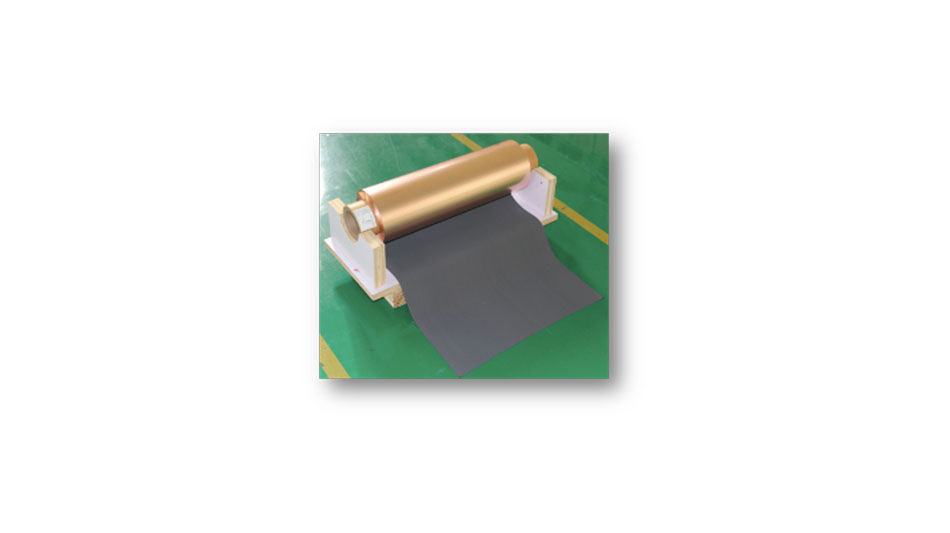

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Low Carbon Developing: JIMA Copper are one type of new material and important link national “low carbon development” strategy new industry, JIMA Copper still upholds the low carbon environmental protection concept from purchase of raw material, manufacturing and sales and constantly adopts new technology, new equipment to improve workmanship and production efficiency and make all types of indexes reach the advanced level in the industry in aspects of energy saving and emission reduction.

Features

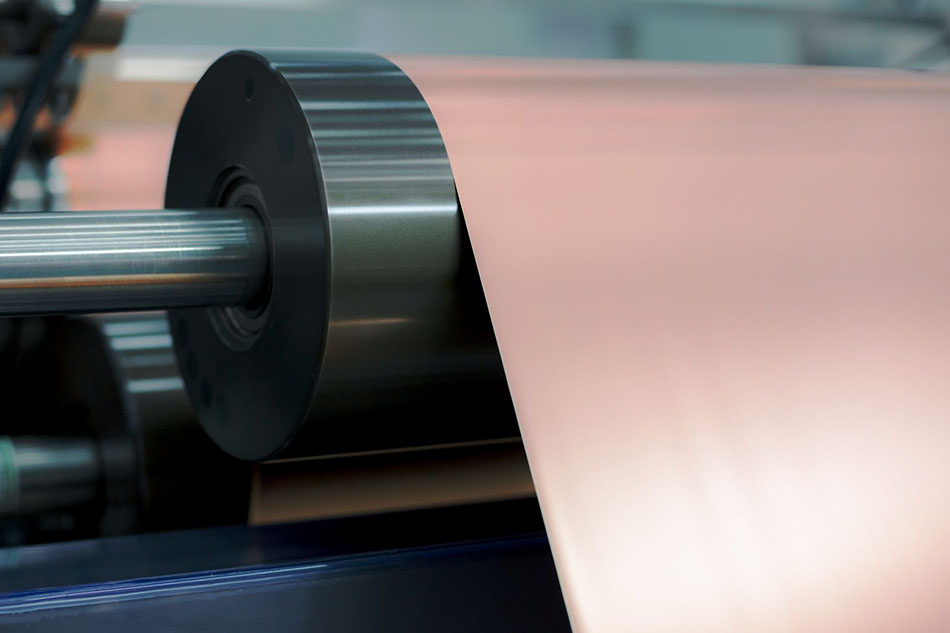

● Reverse treated copper foil

● Low profile

● High MIT

● Good etchability

● The treated foil is pink

Application

● Multilayer board

● High frequency

● EMI

Typical Properties of Low Coarsening Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

≤12. |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥103 |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥4.0 |

≥4.6 |

≥5.7 |

≥7.4 |

≥8.0 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

|

|||||

|

H.T.(200°C) |

Minutes |

40 |

|||||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Good quality Copper Foil Rf Shielding - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: kazakhstan, Colombia, Boston, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!