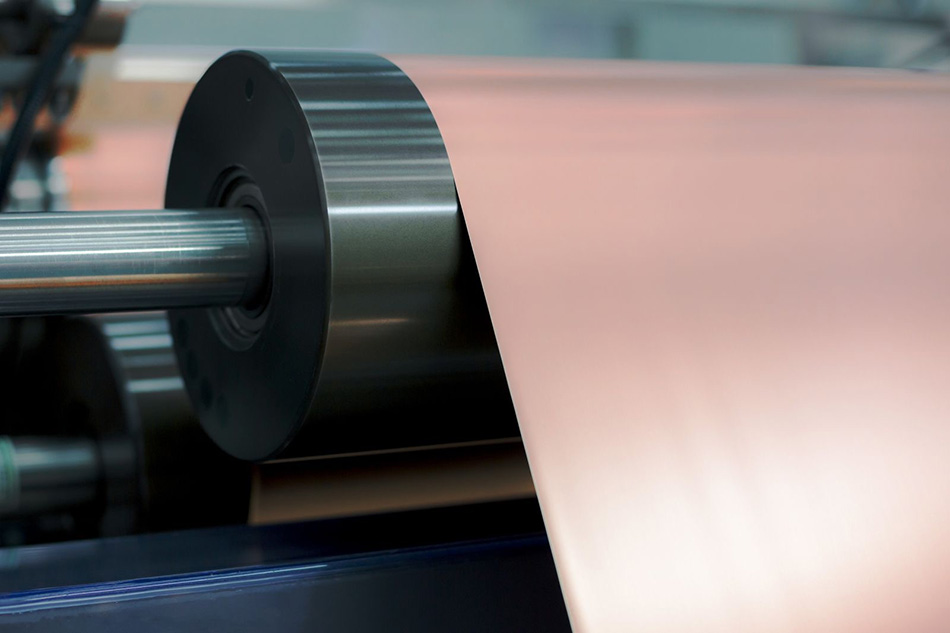

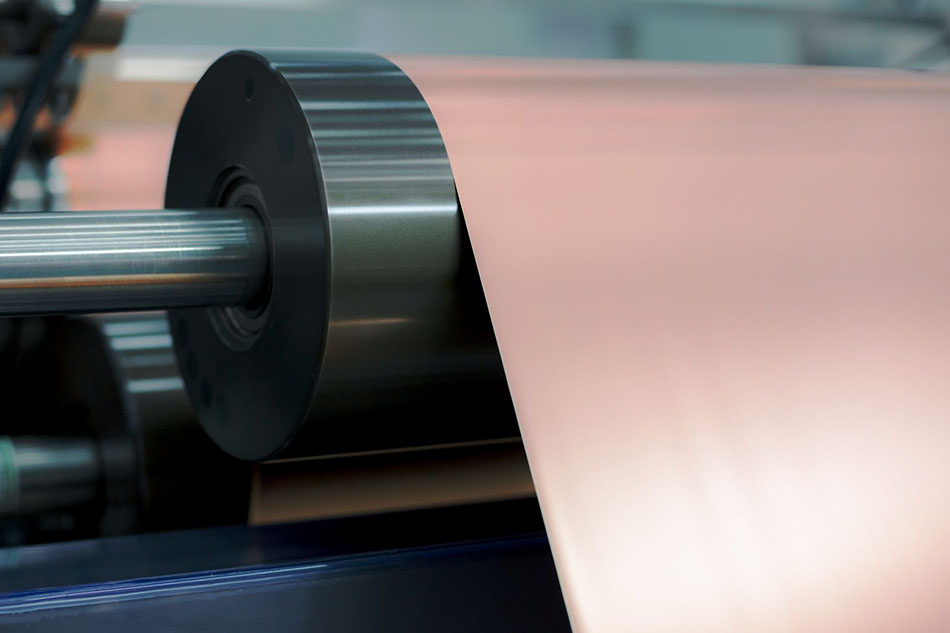

Good Quality Emi Shielding Copper Foil 140um - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM

Good Quality Emi Shielding Copper Foil 140um - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM Detail:

JIMA Copper proprietary ultra low roughness treatment process ensures effective adhesion strength for low Dk film materials, for which adhesion strength is difficult to achieve, without sacrificing transmission properties. Due to the recrystallized base foil, it also offers superior bending characteristics for contributing to the next generation of flexible printed circuits.

Detail

● Thickness: 12um 18um 35um

● Standard Width: 1290mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Lead time: 15-20days

● High precision cutting equipment cut copper foils according to width required by customers.

● Slitting Working Procedure: Conduct slitting, classification, inspection and package according to requirement for quality, width and weight of copper foils of customers.

Features

● Ultra -low profile, with high peel

● Strength and good etchability

● Low coarsening technology

Application

● High speed digital

● Base station/server

● PPO/PPE

● Use Low coarsening technology ,the microstructure makes it an excellent material to apply to high frequency transmission circuit.

● High frequency transmission circuit / High Speed Transmission.

Typical Properties of Hyper Very Low Profile Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||

|

Foil Designation |

|

T |

H |

1 |

IPC-4562A |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||

|

Roughness |

Shiny side (Ra) |

um |

≤0.43 |

IPC-TM-650 2.2.17 |

|||

|

Matte side(Rz) |

um |

1.5-2.0 |

optical method |

||||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥300 |

IPC-TM-650 2.4.18 |

|||

|

H.T.(180°C) |

≥180 |

||||||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥6 |

≥6 |

≥6 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.8 |

≥1.0 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥4.6 |

≥5.7 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

|||

|

H.T.(200°C) |

Minutes |

40 |

|||||

Standard Width,1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Good Quality Emi Shielding Copper Foil 140um - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM , The product will supply to all over the world, such as: Liverpool, Chile, Accra, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we will continue with the most professional and high quality service to provide the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!