Good Quality Emi Shielding Copper Foil 140um - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM

Good Quality Emi Shielding Copper Foil 140um - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM Detail:

Detail

● Thickness: 10um 12um 18um 25um 35um

● Standard Width: 520mm1040mm 1100mm, Max.1300mm; can be cutting as per size request.

● Wooden box package

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

By increasing the density of the roughening treatment particles compared to previous products, this ultra low roughness copper foil boasts stronger adhesion to various substrates without increasing roughness. In addition to adhesion strength, it also offers various other features that enhance functionality and directly improve board reliability, such as long-term heat resistance and chemical resistance.

● Low profile for FCCL

● Grain structure of copper foil leads to high flexibility

● Excellent etching performance

● The treated foil is red or black

● Low profile enables to make fine circuit pattern

Typical application

● Casting and lamination type FCCL

● Fine pattern FPC&PWB

● Chip on flex for LED

● For FPC or Inner layer

● Despite the low roughness, this foil offers high adhesion strength, heat resistance, and high chemical resistance for use in a wide variety of application

Typical properties of Matte Side Treatment Low Profile Copper Foil

| Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

10 |

12 |

16 |

25 |

35 |

IPC-4562A |

|

|

Area Weight |

g/m² |

98±4 |

107±4 |

153± 5 |

228± 8 |

285±10 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥4 |

≥4.6 |

≥5.7 |

≥6.3 |

≥6.9 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

60 |

||||||

Standard Width: 520mm1040mm 1100mm, Max.1300mm May according to the customer request tailor.

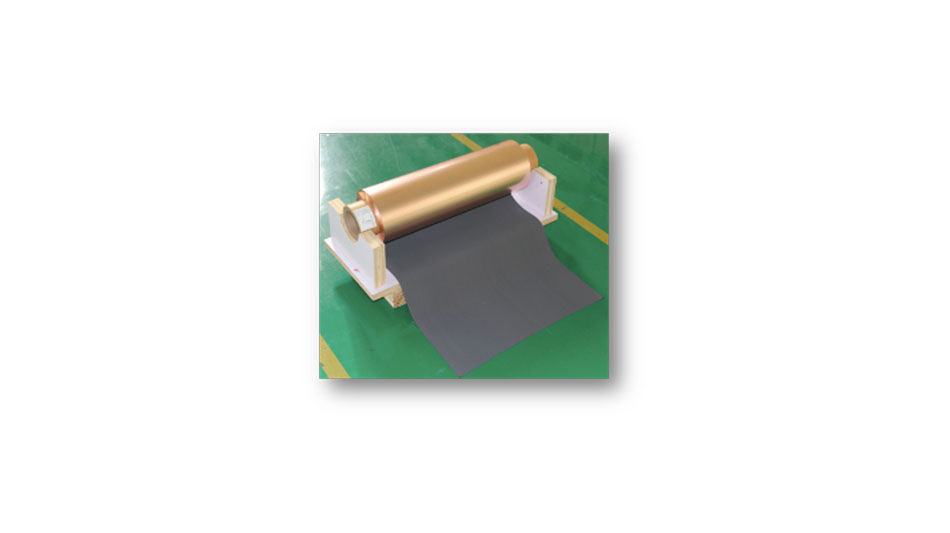

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Good Quality Emi Shielding Copper Foil 140um - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM , The product will supply to all over the world, such as: Belize, Hungary, Canada, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.