Good quality Foil Shield - Low Low Profile Copper Foil (LP -S-P/B) – JM

Good quality Foil Shield - Low Low Profile Copper Foil (LP -S-P/B) – JM Detail:

Detail

● Thickness: 12um 18um 25um 35um 50um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

This foil is mainly used for multilayered PCBs and high-density circuit boards, which require the surface roughness of the foil to be lower than that of regular copper foil so that their performances such as peeling resistance can remain at a high level. It belongs to a special category of electrolytic copper foil with roughness control. Compared with regular electrolytic copper foil, the crystals of LP copper foil are very fine equiaxed grains (<2/zm). They contain lamellar crystals instead of columnar ones, while they feature flat ridges and a low level of surface roughness. They have such merits as better size stability and higher hardness.

● Low profile for FCCL

● High MIT

● Excellent etchability

● The treated foil is pink or black

Application

● 3layer FCCL

● EMI

Typical properties of Low Profile Copper Foil (LP -S-P/B)

|

Classification |

Unit |

Requirement |

Test Method |

||||||||

|

Nominal thickness |

Um |

12 |

18 |

25 |

35 |

50 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

225±8 |

285± 10 |

435±15 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12.2 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

IPC-TM-650 2.3.17 |

|||||||

|

Matte side(Rz) |

um |

≤4.5 |

≤5.0 |

≤6.0 |

≤7.0 |

≤8.0 |

≤12 |

≤14 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||||

|

H.T.(180°C) |

≥138 |

||||||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥5 |

≥8 |

≥10 |

≥12 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C |

≥4 |

≥4 |

≥5 |

≥6 |

≥8 |

≥8 |

≥8 |

||||

|

Resistivity |

Ω.g/m² |

≤0.17 0 |

≤0.1 66 |

≤0.16 2 |

≤0.16 2 |

≤0.16 2 |

IPC-TM-650 2.5.14 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.3 |

≥1.6 |

≥1.6 |

≥2.1 |

IPC-TM-650 2.4.8 |

||||

| Pinholes & Porosity | Number |

No |

IPC-TM-650 2.1.2 |

||||||||

| Anti-oxidization | R.T.(23°C) | Days |

180 |

||||||||

| H.T.(200°C) | Minutes |

30 |

|||||||||

Standard Width,1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

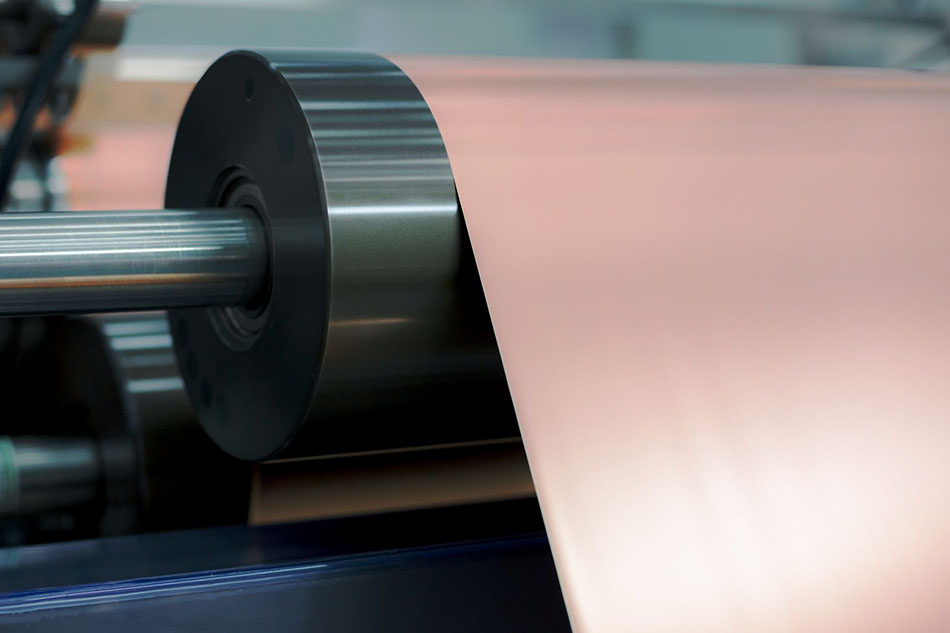

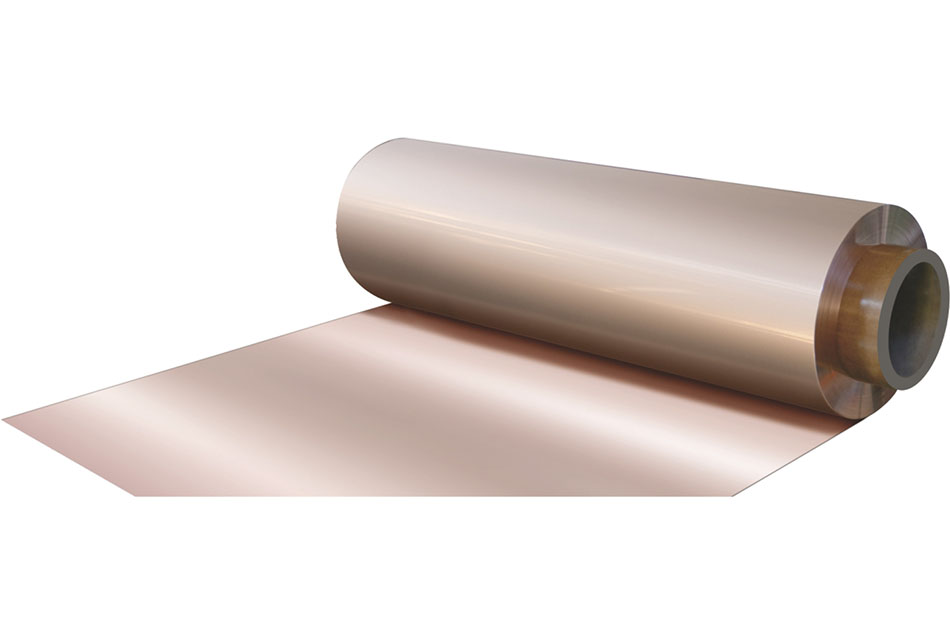

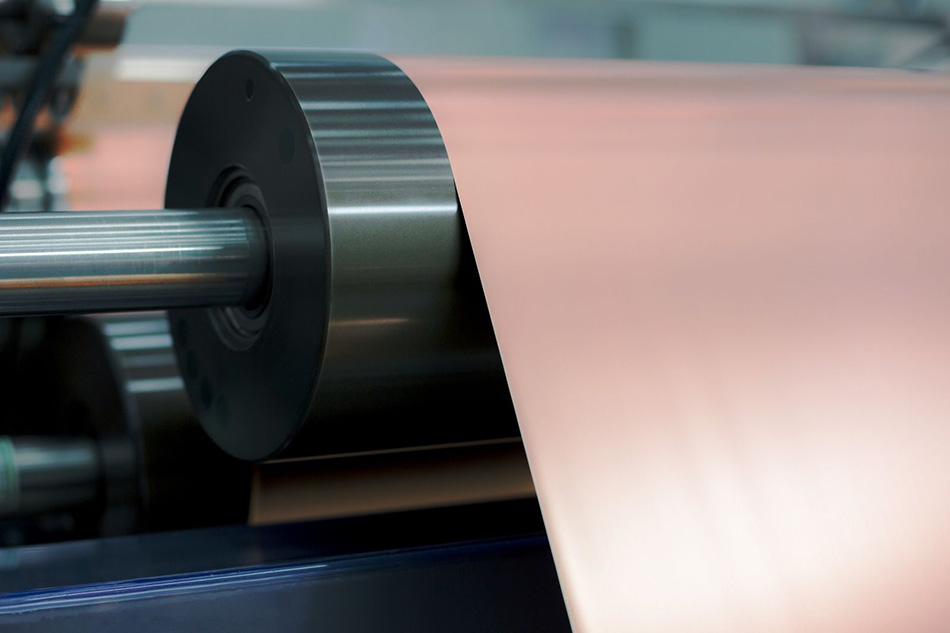

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Good quality Foil Shield - Low Low Profile Copper Foil (LP -S-P/B) – JM , The product will supply to all over the world, such as: Kenya, Costa Rica, Jersey, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.