Good Quality Treated Rolled Copper Foil - High corrosion resistance rolled copper foil (RA Copper Foil with Nickel plating) – JM

Good Quality Treated Rolled Copper Foil - High corrosion resistance rolled copper foil (RA Copper Foil with Nickel plating) – JM Detail:

JIMA Copper

JIMA Copper is a hi-tech enterprise specializing in the production of high-precision copper and rolled foil of copper alloy series. The company has passed ISO9001 international quality management system and ISO14001 international environmental management system certification. With the introduction of international first-class production equipment and technology, the company can produce foil of 4-100 μm thickness and a maximum of 660 mm width, which makes the company the largest in copper foil capacity, the most complete in varieties and the highest in professionalism in rolled copper foil research and production in China.

Specializing in the research, development, promotion and application of new technologies and production of rolled copper foil, JIMA Copper has been recognized as Hi- tech Enterprise, Engineering Technology Research Center of Rolled Copper Foil , provincial Enterprise Technology Center and is a council unit of China Nonferrous Metal Processing Association. The company can steadily provide various specifications of high-precision plain foil (hard foil, soft foil, semi-hard foil, etc.) and surface treatment foil (copper foil with red matte side, copper foil with black matte side, high corrosion resistance rolled copper foil, etc.).The products are widely used in the fields of electromagnetic shielding, heat dissipation, grapheme conductive film production, aerospace, flexible copper clad plate, lithium battery, 5G communication, LED, intelligent automobile, drone, wearable electronic products, etc., and are highly recognized and praised by customers.

And exported to Korea, Japan, Germany, the United States, Russia, India and other countries.

Rolled Copper Foil Specification & Application

|

Item |

Alloy |

Thickness (um) |

Width(mm) |

Application |

|

Rolled copper foil for graphene |

C1020 |

12um 18um 25um 35um 50um |

≤630 |

Grapheme conductive film production |

|

Rolled Copper Foil with Black/red treatment |

C1100 |

6um 9um 12um 18um 22um 35um 50um 70um |

≤630 |

Flexibility LED, FCCL, Flexible Printed Circuit, flexible copper clad plate, |

|

Plain Copper Foil |

C1100 |

6um 9um 12um 18um 35um 50um 70um |

≤630 |

l Energy storage, Power., Electric Vehicles Li-ion Battery, 5G Mobile antenna, Heat dissipation |

|

High corrosion resistance rolled copper foil(RA Copper Foil _with Nickel plating) |

C1100 |

12um 18um 25um 35um 50um |

≤630 |

Mess mobile model. will be applied almost of Samsung mobile device |

Typical Properties Of Rolled Copper Foil with Nickel Plating

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

12 |

18 |

25 |

35 |

50 |

GB/T29847-2013 |

|

|

Area Weight |

g/m² |

107±3 |

160±4 |

222±4 |

311±5 |

445±5 |

GB/T29847-2013 |

|

|

Cu Purity(C1020) |

% |

≥99.96 |

GB/T5121 |

|||||

|

Surface roughness |

սm |

≤0.2 |

GB/T29847-2013 |

|||||

|

Tensile Strength |

180℃/30min |

N/m² |

160-180 |

170-190 |

180-210 |

180-210 |

200-220 |

GB/129847-2013 |

|

Elongation Rate |

180℃/30min |

% |

≥7 |

≥8 |

≥9 |

≥11 |

≥13 |

GB/129847-2013 |

|

Surface Quality |

Uniform Color, No Wrinkle, No Scratche, No Pit and Salient Point | |||||||

|

Corrosion Resistance |

5%NaCl,35℃,24h |

OK |

||||||

|

Storage Condition |

|

Temperature≤25°C, Relative Humidity≤60%, 180 days |

||||||

|

Product Advantage |

|

Clean appearance, Superior Wear Resistance, And Corrosion Resistance |

||||||

Remark

1. Nickel plating Thickness: 0.3-0.6um

2. Can supply single side plating and double side plating

3. Supply Sample

4. Export Wooden box package

5. ID: 76MM

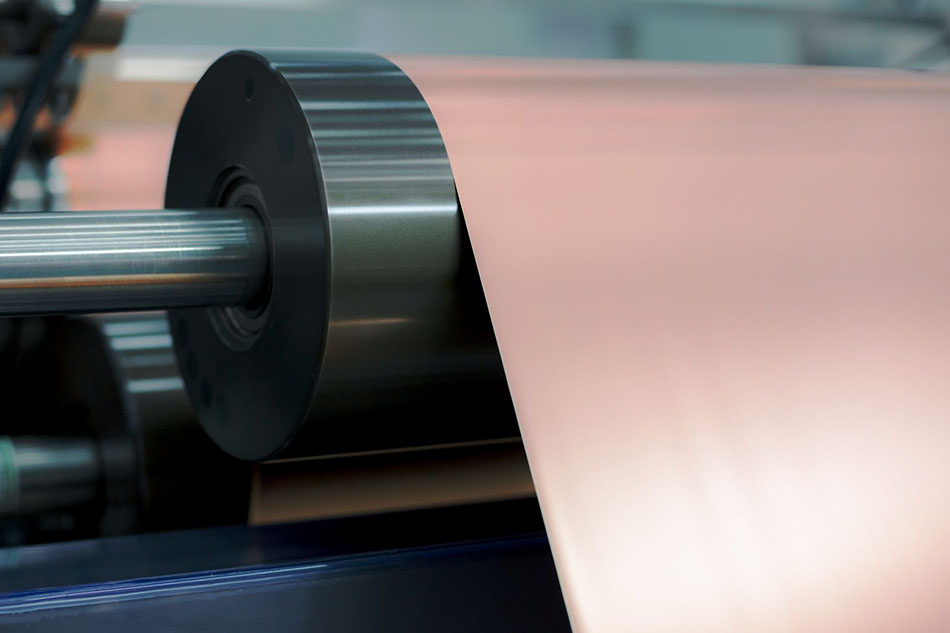

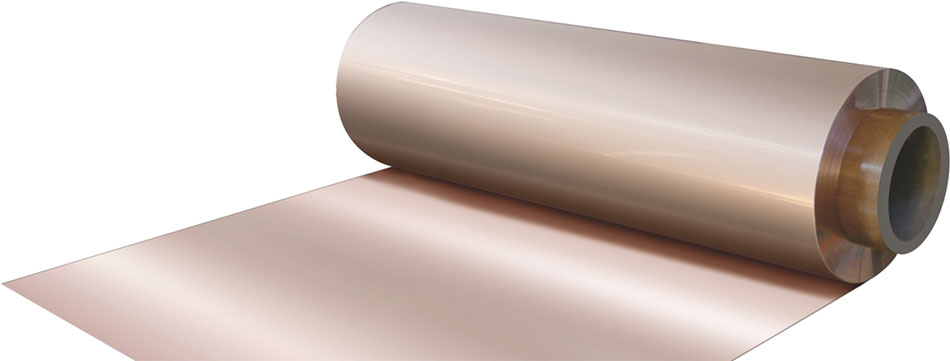

RA Copper Foil & Wooden Box Package Photos

Product detail pictures:

Related Product Guide:

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Good Quality Treated Rolled Copper Foil - High corrosion resistance rolled copper foil (RA Copper Foil with Nickel plating) – JM , The product will supply to all over the world, such as: Jeddah, Malta, Israel, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.