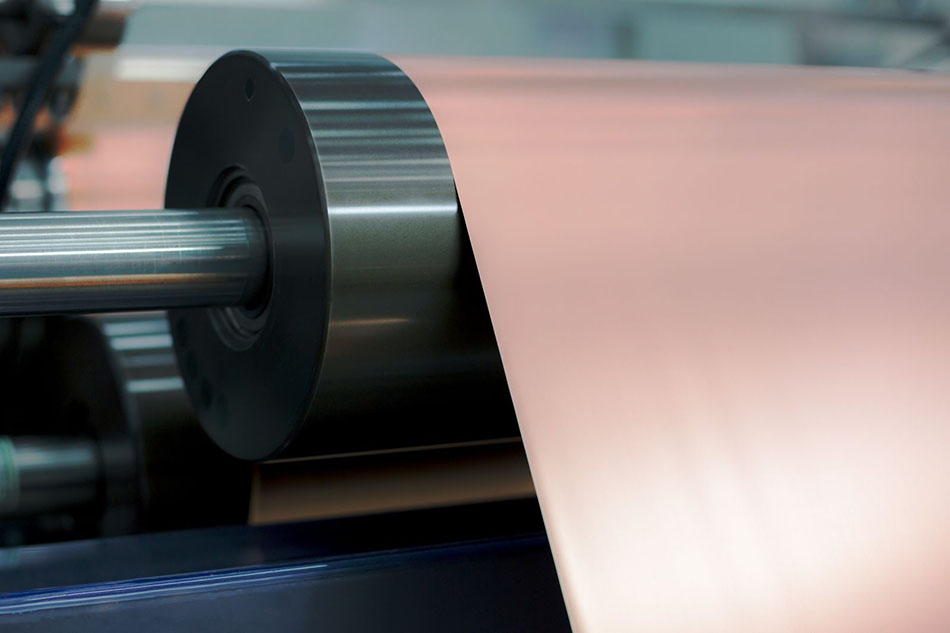

High Performance Insulated Copper Foil - Reverse Treated Electrolytic Copper Foil – JM

High Performance Insulated Copper Foil - Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, range: 300-1300mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● High precision cutting equipment cut copper foils according to width required by customers.

● The electron microscope and energy disperse spectroscopy equipment guarantee the quality of final product before delivery.

Features

● Reverse treated copper foil

● Low profile, with high peel strength

● Excellent etchability

● The treated foil is pink

Application

● High frequency, applying to hydrocarbon board

● High Tg

● Fine circuit pattern

Typical properties of Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

|

|

|

Test Method |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

4.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.2 |

≥1.4 |

≥1.8 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.7 |

≥7.4 |

≥8.0 |

≥10.2 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

40 |

||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for High Performance Insulated Copper Foil - Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Birmingham, Burundi, azerbaijan, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.