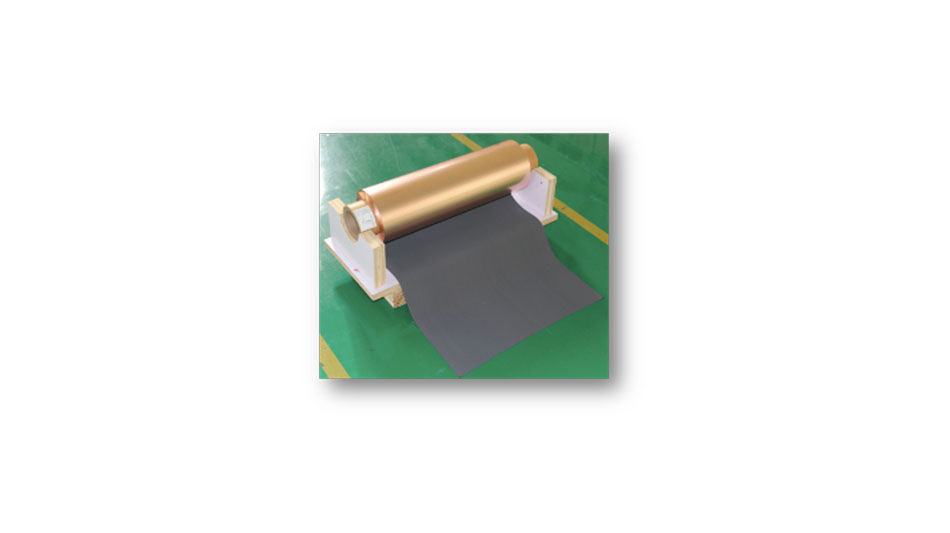

High Quality Copper Coil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM

High Quality Copper Coil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Low Carbon Developing: JIMA Copper are one type of new material and important link national “low carbon development” strategy new industry, JIMA Copper still upholds the low carbon environmental protection concept from purchase of raw material, manufacturing and sales and constantly adopts new technology, new equipment to improve workmanship and production efficiency and make all types of indexes reach the advanced level in the industry in aspects of energy saving and emission reduction.

Features

● Reverse treated copper foil

● Low profile

● High MIT

● Good etchability

● The treated foil is pink

Application

● Multilayer board

● High frequency

● EMI

Typical Properties of Low Coarsening Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

≤12. |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥103 |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥4.0 |

≥4.6 |

≥5.7 |

≥7.4 |

≥8.0 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

|

|||||

|

H.T.(200°C) |

Minutes |

40 |

|||||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for High Quality Copper Coil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Johannesburg, India, Monaco, For anyone who is keen on any of our items right after you view our product list, you should definitely feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We're always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!