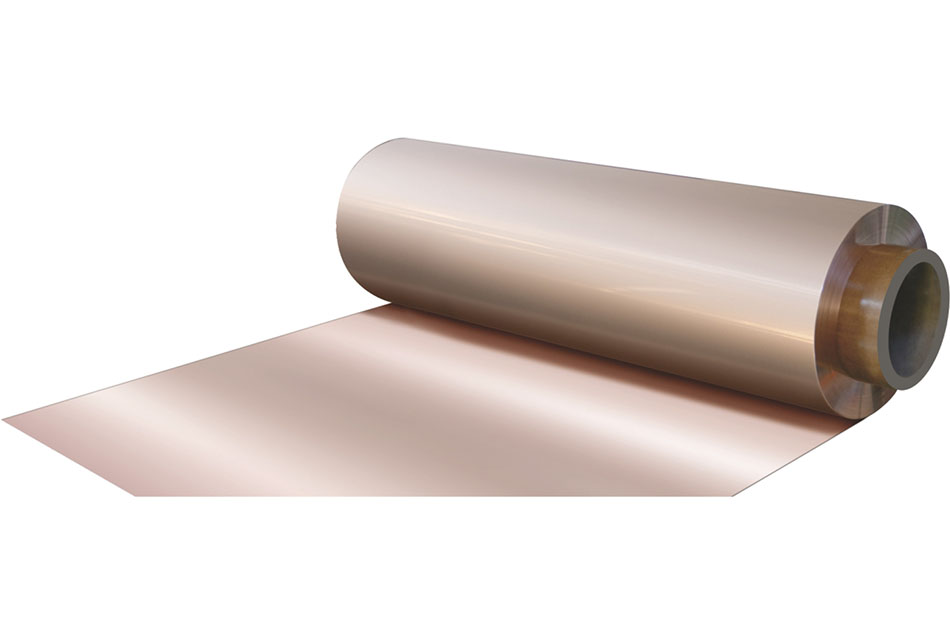

Leading Manufacturer for Copper Foil Hte Pcb - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM

Leading Manufacturer for Copper Foil Hte Pcb - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM Detail:

JIMA Copper proprietary ultra low roughness treatment process ensures effective adhesion strength for low Dk film materials, for which adhesion strength is difficult to achieve, without sacrificing transmission properties. Due to the recrystallized base foil, it also offers superior bending characteristics for contributing to the next generation of flexible printed circuits.

Detail

● Thickness: 12um 18um 35um

● Standard Width: 1290mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Lead time: 15-20days

● High precision cutting equipment cut copper foils according to width required by customers.

● Slitting Working Procedure: Conduct slitting, classification, inspection and package according to requirement for quality, width and weight of copper foils of customers.

Features

● Ultra -low profile, with high peel

● Strength and good etchability

● Low coarsening technology

Application

● High speed digital

● Base station/server

● PPO/PPE

● Use Low coarsening technology ,the microstructure makes it an excellent material to apply to high frequency transmission circuit.

● High frequency transmission circuit / High Speed Transmission.

Typical Properties of Hyper Very Low Profile Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||

|

Foil Designation |

|

T |

H |

1 |

IPC-4562A |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||

|

Roughness |

Shiny side (Ra) |

um |

≤0.43 |

IPC-TM-650 2.2.17 |

|||

|

Matte side(Rz) |

um |

1.5-2.0 |

optical method |

||||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥300 |

IPC-TM-650 2.4.18 |

|||

|

H.T.(180°C) |

≥180 |

||||||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥6 |

≥6 |

≥6 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.8 |

≥1.0 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥4.6 |

≥5.7 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

|||

|

H.T.(200°C) |

Minutes |

40 |

|||||

Standard Width,1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Leading Manufacturer for Copper Foil Hte Pcb - Hyper Very Low Profile Copper Foil For High Speed Transmission – JM , The product will supply to all over the world, such as: Cologne, Toronto, Swiss, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.