Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electrolytic Copper Foil For High Speed Digital – JM

Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electrolytic Copper Foil For High Speed Digital – JM Detail:

Detail

● Thickness: 12um 18um 35um

● Standard Width: 1290mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Lead time: 10-20days

● Exquisite equipment internationally excellent: JIMA copper possesses internationally first-rate electrolytic copper foils products equipment and precision inspection and monitoring devices. Domestic and overseas advanced machines and equipment for production, processing, packing and inspection of electrolytic copper foil will be introduced constantly along with scale expansion and business development of the company.

Features

● Ultra- low profile ,with high peel

● Strength and good etchability

● Low coarsening technology

Application

● High speed digital

● Base station/server

● PPO/PPE

Typical properties of Double Side Treated Copper foil For HDI

|

Classification |

Unit |

Requirement |

Test Method |

||||

|

Foil Designation |

|

T |

H |

1 |

IPC-4562A |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||

|

Roughness |

Shiny side (Ra) |

um |

≤0.43 |

IPC-TM-650 2.2.17 |

|||

|

Matte side(Rz) |

um |

1.0-1.5 |

href=”https://cn.bing.com/dict/search?q=optical&FORM=BDVSP6&cc=cn” optical method |

||||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥300 |

IPC-TM-650 2.4.18 |

|||

|

H.T.(180°C) |

≥180 |

||||||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥6 |

≥6 |

≥6 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.8 |

≥1.0 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥4.6 |

≥5.7 |

||||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

|||

|

H.T.(200°C) |

Minutes |

40 |

|||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

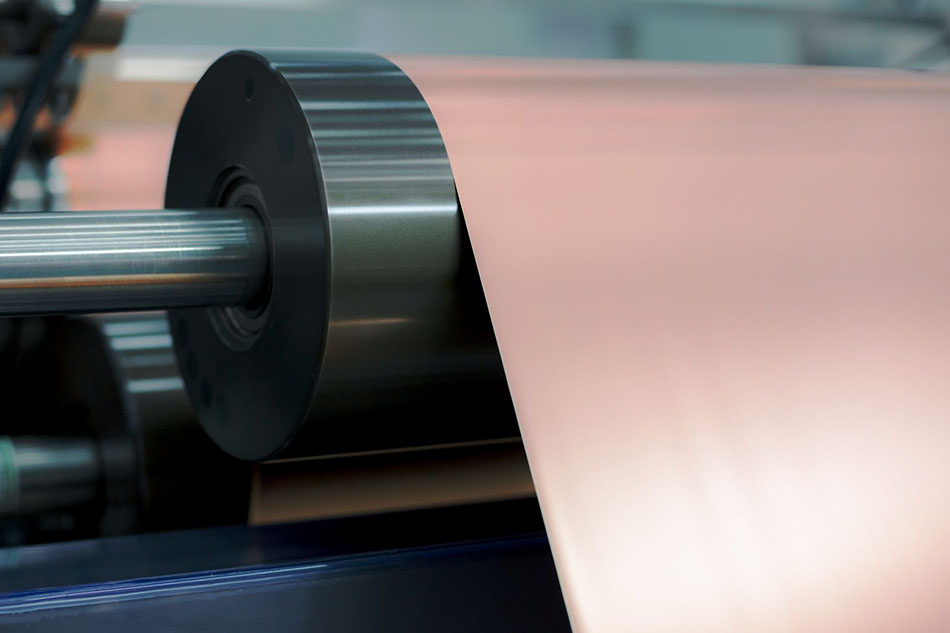

Product detail pictures:

Related Product Guide:

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Manufacturer for Reverse Treated Electrodeposited Copper Foil - Electrolytic Copper Foil For High Speed Digital – JM , The product will supply to all over the world, such as: Sri Lanka, Mombasa, Korea, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.