Manufacturing Companies for Copper Foil Us - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM

Manufacturing Companies for Copper Foil Us - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM Detail:

Detail

● Thickness: 10um 12um 18um 25um 35um

● Standard Width: 520mm1040mm 1100mm, Max.1300mm; can be cutting as per size request.

● Wooden box package

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

By increasing the density of the roughening treatment particles compared to previous products, this ultra low roughness copper foil boasts stronger adhesion to various substrates without increasing roughness. In addition to adhesion strength, it also offers various other features that enhance functionality and directly improve board reliability, such as long-term heat resistance and chemical resistance.

● Low profile for FCCL

● Grain structure of copper foil leads to high flexibility

● Excellent etching performance

● The treated foil is red or black

● Low profile enables to make fine circuit pattern

Typical application

● Casting and lamination type FCCL

● Fine pattern FPC&PWB

● Chip on flex for LED

● For FPC or Inner layer

● Despite the low roughness, this foil offers high adhesion strength, heat resistance, and high chemical resistance for use in a wide variety of application

Typical properties of Matte Side Treatment Low Profile Copper Foil

| Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

10 |

12 |

16 |

25 |

35 |

IPC-4562A |

|

|

Area Weight |

g/m² |

98±4 |

107±4 |

153± 5 |

228± 8 |

285±10 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

≤2.5 |

IPC-TM-650 2.3.17 |

|

Matte side(Rz) |

um |

≤4.0 |

≤4.5 |

≤5.5 |

≤6.0 |

≤8.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥260 |

≥260 |

≥280 |

≥280 |

≥280 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C) |

≥180 |

≥180 |

≥180 |

≥180 |

≥180 |

|||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥5 |

≥6 |

≥7 |

≥8 |

≥8 |

||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

0.8 |

1.0 |

1.1 |

1.2 |

IPC-TM-650 2.4.8 |

|

|

|

lbs/in |

≥4 |

≥4.6 |

≥5.7 |

≥6.3 |

≥6.9 |

||

|

Pinholes & porosity |

Number |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

|

180 |

|

||||

|

R.T.(200°C) |

|

60 |

||||||

Standard Width: 520mm1040mm 1100mm, Max.1300mm May according to the customer request tailor.

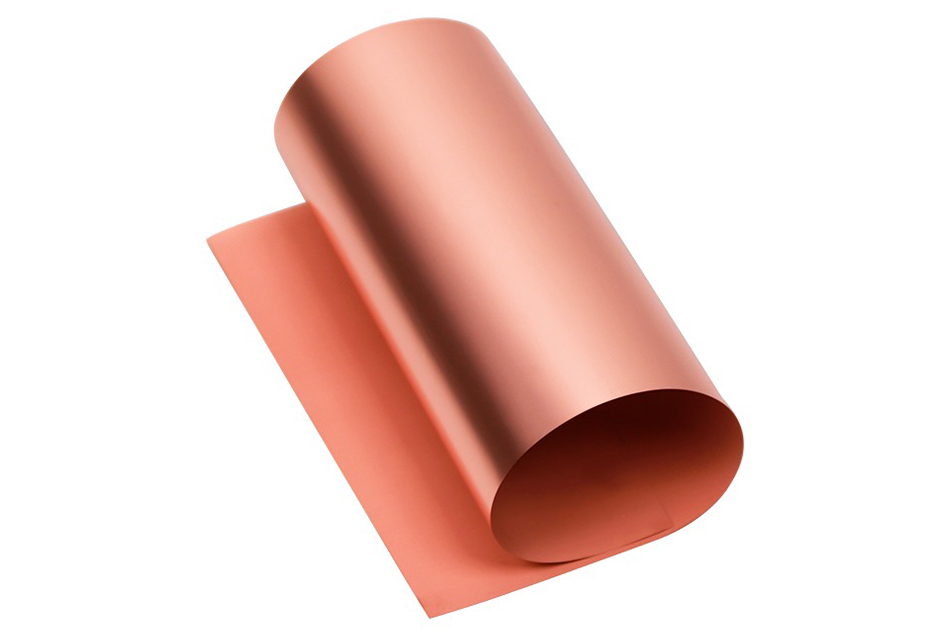

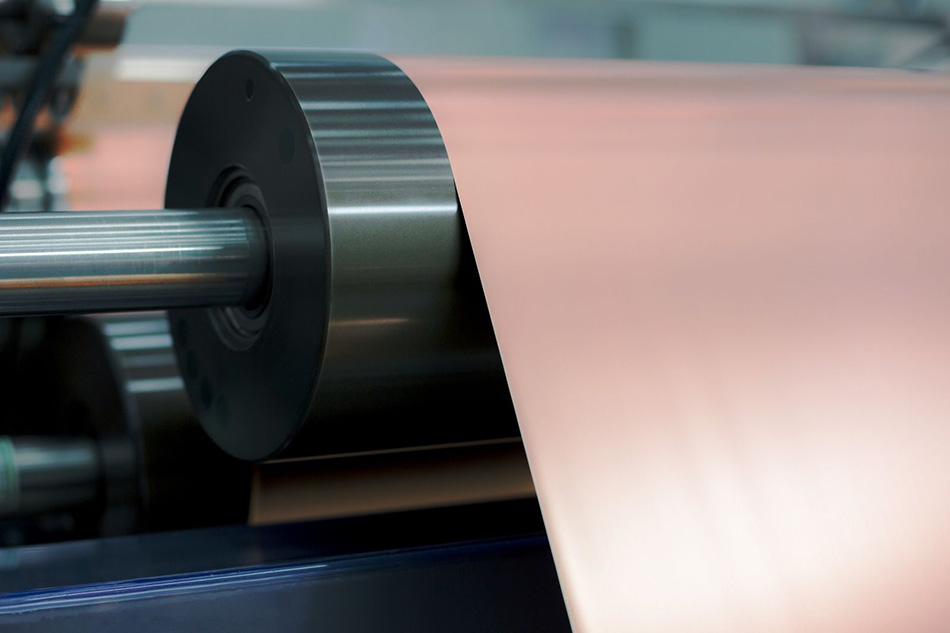

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for Manufacturing Companies for Copper Foil Us - Matte Side Treatment Low Profile Copper in Black/red (LP-S-B/R) – JM , The product will supply to all over the world, such as: Slovenia, Cyprus, Swedish, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.