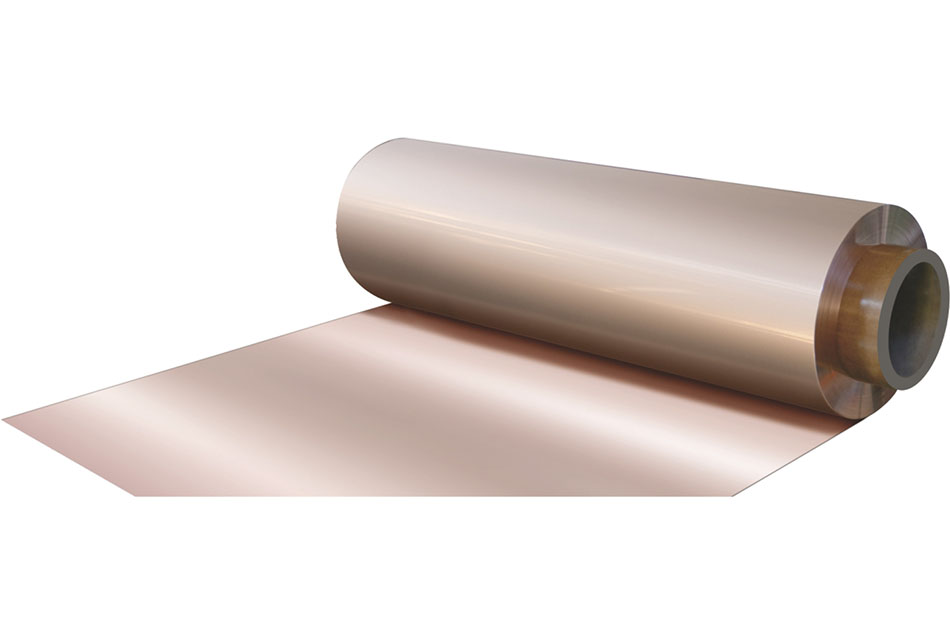

OEM/ODM Manufacturer Copper Foil 0.0005 - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM

OEM/ODM Manufacturer Copper Foil 0.0005 - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Low Carbon Developing: JIMA Copper are one type of new material and important link national “low carbon development” strategy new industry, JIMA Copper still upholds the low carbon environmental protection concept from purchase of raw material, manufacturing and sales and constantly adopts new technology, new equipment to improve workmanship and production efficiency and make all types of indexes reach the advanced level in the industry in aspects of energy saving and emission reduction.

Features

● Reverse treated copper foil

● Low profile

● High MIT

● Good etchability

● The treated foil is pink

Application

● Multilayer board

● High frequency

● EMI

Typical Properties of Low Coarsening Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

≤12. |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥103 |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥4.0 |

≥4.6 |

≥5.7 |

≥7.4 |

≥8.0 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

|

|||||

|

H.T.(200°C) |

Minutes |

40 |

|||||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for OEM/ODM Manufacturer Copper Foil 0.0005 - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Oslo, Paraguay, Slovakia, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!