One of Hottest for Copper Foil Insulation - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM

One of Hottest for Copper Foil Insulation - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Low Carbon Developing: JIMA Copper are one type of new material and important link national “low carbon development” strategy new industry, JIMA Copper still upholds the low carbon environmental protection concept from purchase of raw material, manufacturing and sales and constantly adopts new technology, new equipment to improve workmanship and production efficiency and make all types of indexes reach the advanced level in the industry in aspects of energy saving and emission reduction.

Features

● Reverse treated copper foil

● Low profile

● High MIT

● Good etchability

● The treated foil is pink

Application

● Multilayer board

● High frequency

● EMI

Typical Properties of Low Coarsening Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

≤12. |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥103 |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥4.0 |

≥4.6 |

≥5.7 |

≥7.4 |

≥8.0 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

|

|||||

|

H.T.(200°C) |

Minutes |

40 |

|||||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

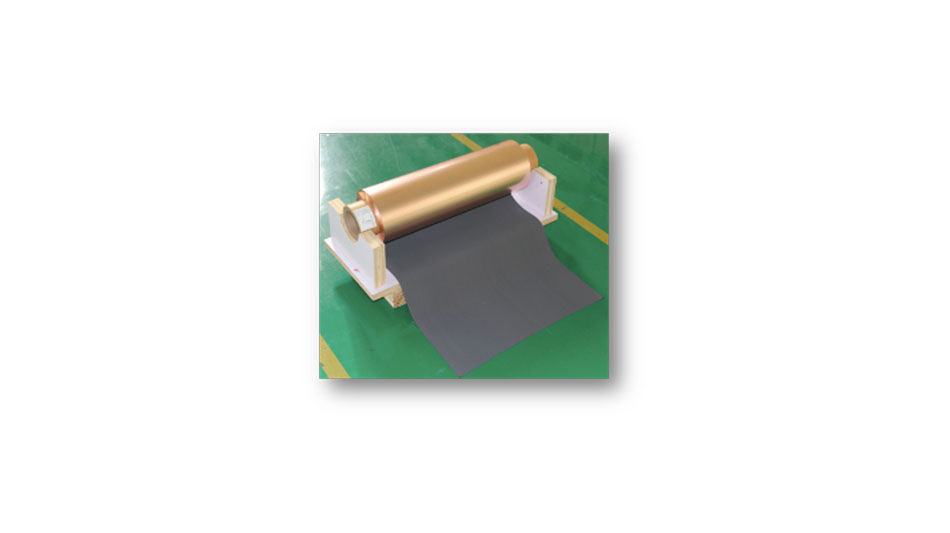

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for One of Hottest for Copper Foil Insulation - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Malawi, Singapore, Vancouver, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!