One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM

One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, range: 300-1300mm, can be cutting as size request.

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

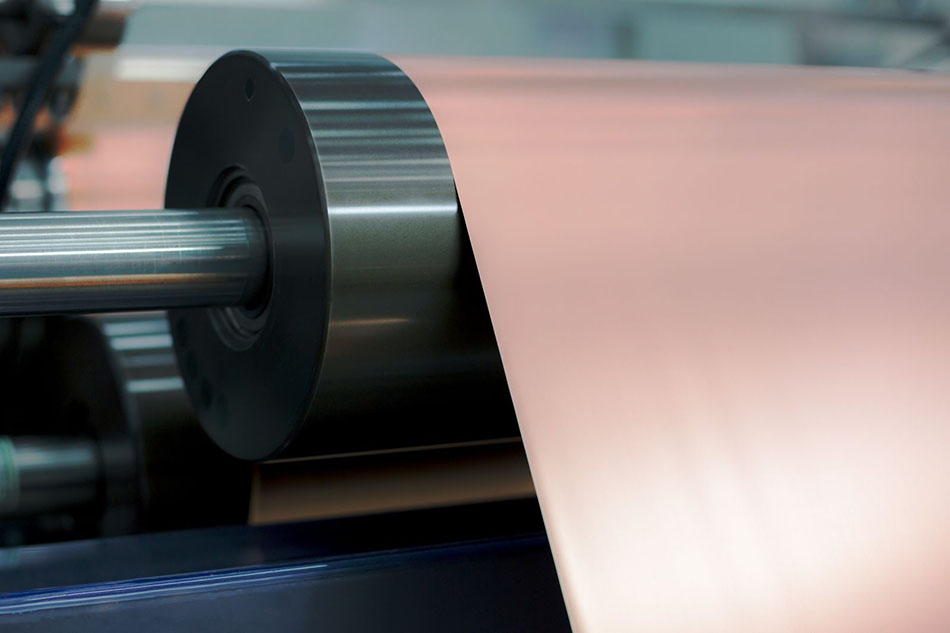

● High precision cutting equipment cut copper foils according to width required by customers.

● The electron microscope and energy disperse spectroscopy equipment guarantee the quality of final product before delivery.

Features

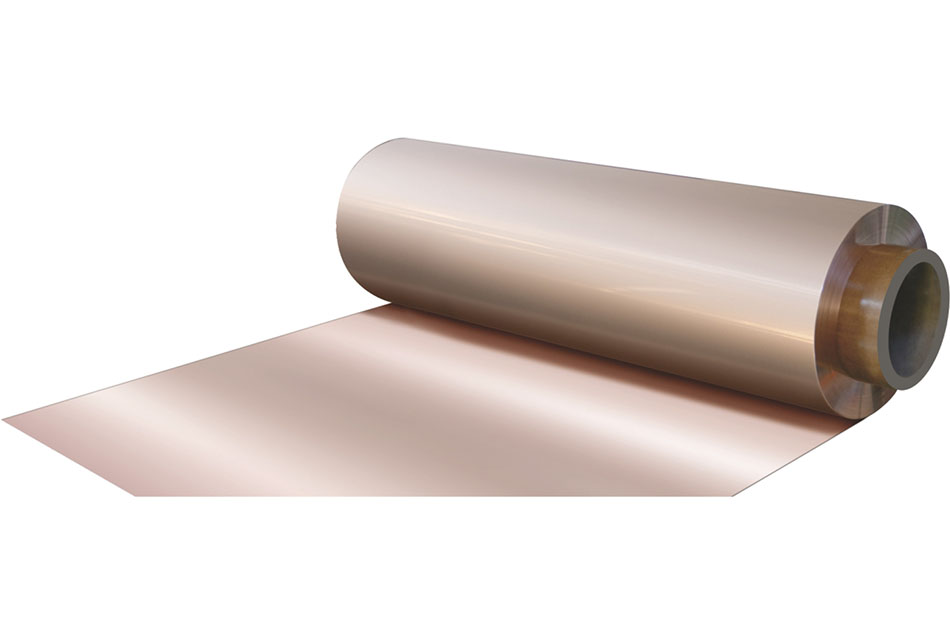

● Reverse treated copper foil

● Low profile, with high peel strength

● Excellent etchability

● The treated foil is pink

Application

● High frequency, applying to hydrocarbon board

● High Tg

● Fine circuit pattern

Typical properties of Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

|

|

|

Test Method |

||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

4.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥1.0 |

≥1.2 |

≥1.4 |

≥1.8 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥5.7 |

≥7.4 |

≥8.0 |

≥10.2 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

40 |

||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for One of Hottest for Copper Foil Insulation - Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Birmingham, Libya, Argentina, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.