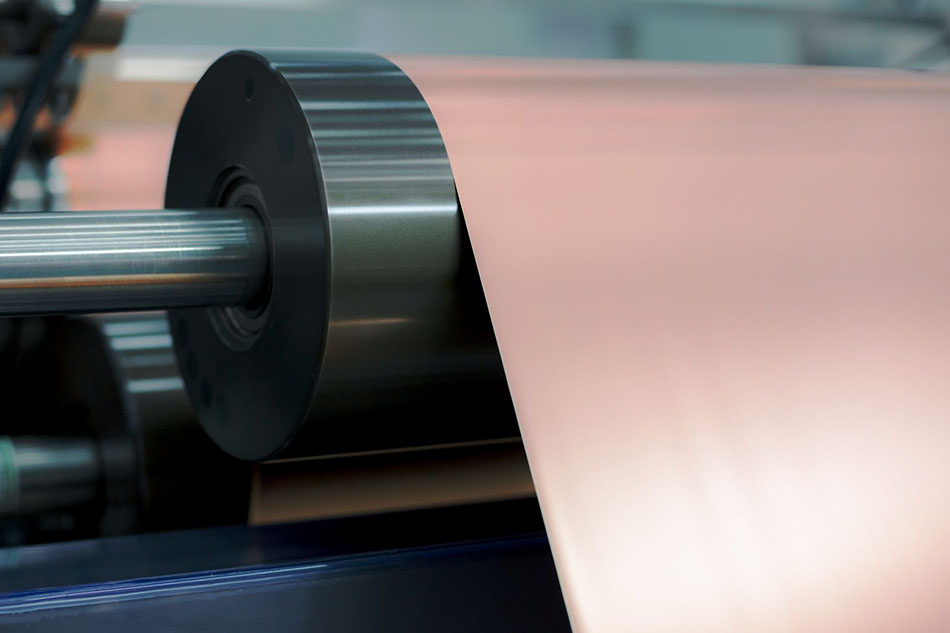

Special Design for 9um Copper Foil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM

Special Design for 9um Copper Foil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um 105um

● Standard Width: 1290mm, can be cutting as size request

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

● Low Carbon Developing: JIMA Copper are one type of new material and important link national “low carbon development” strategy new industry, JIMA Copper still upholds the low carbon environmental protection concept from purchase of raw material, manufacturing and sales and constantly adopts new technology, new equipment to improve workmanship and production efficiency and make all types of indexes reach the advanced level in the industry in aspects of energy saving and emission reduction.

Features

● Reverse treated copper foil

● Low profile

● High MIT

● Good etchability

● The treated foil is pink

Application

● Multilayer board

● High frequency

● EMI

Typical Properties of Low Coarsening Reverse Treated Electrolytic Copper Foil

|

Classification |

Unit |

Requirement |

Test Method |

||||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

105 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

870±30 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

||||||

|

Roughness |

Shiny side (Ra) |

um |

≤3.0 |

IPC-TM-650 2.2.17 |

|||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

≤12. |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥207 |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥103 |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥2 |

≥2 |

≥3 |

≥3 |

≥4 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥2 |

≥2 |

≥2 |

≥3 |

≥3 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.7 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥4.0 |

≥4.6 |

≥5.7 |

≥7.4 |

≥8.0 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

||||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

180 |

|

|||||

|

H.T.(200°C) |

Minutes |

40 |

|||||||

Standard Width, 1295(±1)mm, Width range:200-1340mm. May according to the customer request tailor.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Special Design for 9um Copper Foil - Low Coarsening Reverse Treated Electrolytic Copper Foil – JM , The product will supply to all over the world, such as: Oman, Cannes, Bahrain, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!