Special Design for 9um Copper Foil - Reverse Treated Copper Foil – JM

Special Design for 9um Copper Foil - Reverse Treated Copper Foil – JM Detail:

Detail

● Thickness: 12um 18um 35um 70um

● Standard Width: 1290mm, can be cutting as size request.

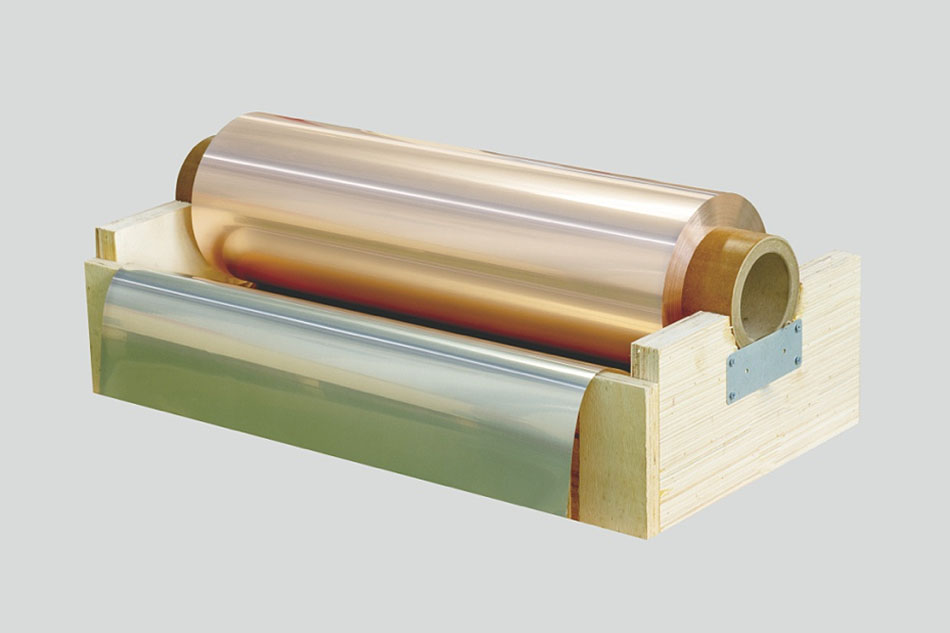

● Wooden box package

● ID: 76 mm, 152 mm

● Length: Customized

● Sample can be supply

Features

● Reverse treated copper foil

● Ultra-low roughness

● Excellent etchability

● The treated foil is pink

Application

● Server/switch/storage

● PPO/PPE

● Mid-low/low/ultra-low loss

Originate from the strict management and control of electrolytic copper production procedure.

JIMA Copper adopts advanced fabrication workmanship and management concept to exercise strict and scientific management for production of copper foil. in light of the need in links such as manufacturing and inspection of copper foil, this company builds 100000-level dustless workshop to ensure production of high performance and high quality copper foils products.

Typical Properties of Reverse Treated Copper Foil for Server/switch/storage

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

um |

12 |

18 |

35 |

70 |

IPC-4562A |

||

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

585± 20 |

IPC-TM-650 2.2.12 |

||

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

Roughness |

Shiny side (Ra) |

um |

2.0 |

IPC-TM-650 2.2.17 |

||||

|

Matte side(Rz) |

um |

≤5.0 |

≤6.0 |

≤8.0 |

≤10 |

|||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥276 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥138 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥4 |

≥4 |

≥8 |

≥12 |

IPC-TM-650 2.4.18 |

|

|

H.T.(180°C) |

≥3 |

≥4 |

≥4 |

≥4 |

||||

|

Peel Strength(FR-4) |

N/mm |

≥0.6 |

≥0.8 |

≥1.0 |

≥1.0 |

IPC-TM-650 2.4.8 |

||

|

Lbs/in |

≥3.4 |

≥4.6 |

≥5.7 |

≥5.7 |

||||

|

Pinholes & porosity |

Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

|

Anti-oxidization |

R.T.(23°C) |

Days |

90 |

|

||||

|

H.T.(200°C) |

Minutes |

40 |

||||||

Standard Width, 1295(±1)mm, Width range: 200-1340mm. May according to the customer request tailor.

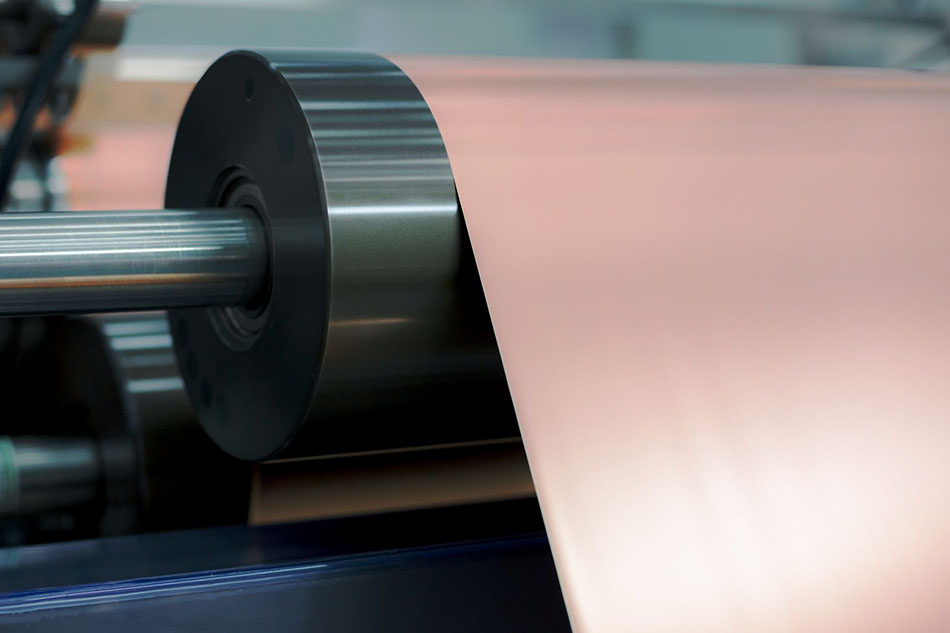

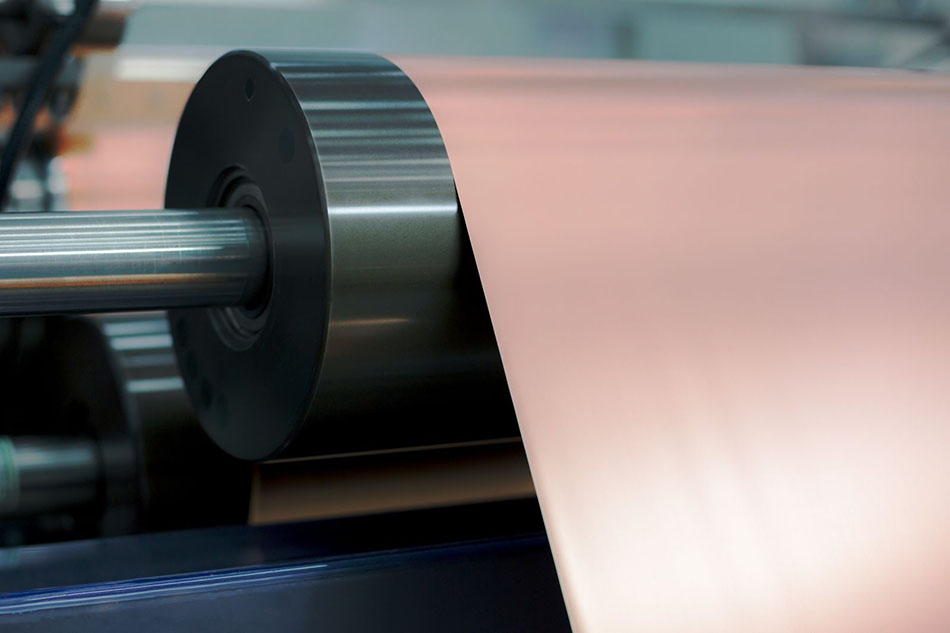

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for Special Design for 9um Copper Foil - Reverse Treated Copper Foil – JM , The product will supply to all over the world, such as: Salt Lake City, United Arab Emirates, Philadelphia, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!