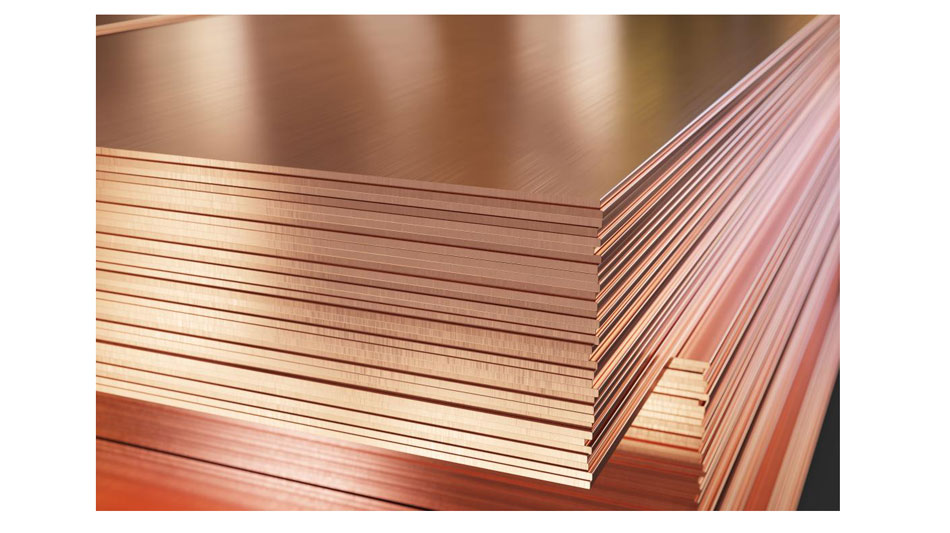

Thick Copper Plate and Width Copper Sheet

1.Widely used in radio frequency cables, transformers, relays, hi-fi box cables, contactors, frequency converters, etc

2.Function: It is suitable for making power transmission materials, conductive components, electrical parts, electrode materials and corrosion-resistant components,

| (mm) Thickness |

(mm) Toler ance |

(mm) Width |

(mm) Toler ance |

(mm) Panel length |

(mm) Toler anee |

||||||

| 0.1~0.15 | ±0.003 | 17~90 | ±0.03 | 800~3200 | ±1 | ||||||

| 0.16~0.4 | ±0.005 | 91~150 | ±0.05 | ||||||||

| 0.41~0.8 | ±0.015 | 151~300 | ±0.1 | ||||||||

| 0.8~1.5 | ±0.03 | 301~1350 | ±0.2 | ||||||||

| 1.51~4.0 | ±0.05 | ||||||||||

| 4.0~15 | ≤1800 | ||||||||||

| Remarks:Please contact us before hand if there are any special requirements on tolerance of products. | |||||||||||

| Alloy | Chemieal Composition & Physical Properties | |||||||||||||

| Cu | P | 0 | [g/cm²] Specifie |

[%IACS] Electrical conductivity |

[μΩ.cm] Resistivity |

[KN/mm²] Modulus of elasticity |

||||||||

| C11000 | ≥99.90 | ... | ... | 8.94 | ≥98 | 1.75 | 117 | |||||||

| C10200 | ≥99.95 | ≤0.001 | ≤0.001 | 8.94 | ≥100 | 1.724 | 117.2 | |||||||

| Alloy | Temper | Rm/(N/mm²) Tensile Strength |

A₁1.g/% Elongtion |

Hardness | |||||||||||

| GB | JIS | ASTM | GB | JIS | ASTM | GB | JIS | ASTM | GB | JIS | ASTM | GB(HV) | JIS(HV) | ASTM(HR) | |

| T2 | C1100 | C11000 |

|

0 | 061 | ≥195 | ≥195 | ≤235 | ≥30 | ≥30 | ≤70 | .. | .. | ||

| Y4 | 1/4H | H01 | 215-275 | 215-285 | 235-290 | ≥25 | ≥20 | 60-90 | 55-100 | ||||||

| Y2 | 1/2H | H02 | 245-345 | 235-315 | 255-315 | ≥8 | ≥10 | 80-110 | 75-120 | ||||||

| Y | H | .. | 295-380 | ≥275 | .. | ≥3 | 90-120 | ≥80 | |||||||

| T | .. | ≥350 | .. | .. | ≥110 | ||||||||||

| TU1 | .. | .. |

|

.. | .. | ≥195 | .. | .. | ≥30 | .. | .. | ≤70 | .. | .. | |

| Y4 | 215-275 | ≥25 | 60-90 | ||||||||||||

| Y2 | 245-345 | ≥8 | 80-110 | ||||||||||||

| Y | 295-380 | ≥3 | 90-120 | ||||||||||||

| T | ≥350 | ≥110 | |||||||||||||

| TU2 | .. | .. |

|

.. | .. | ≥195 | .. | .. | 多30 | .. | .. | ≤70 | .. | .. | |

| Y4 | 215-275 | ≥25 | 60-90 | ||||||||||||

| Y2 | 245-345 | ≥8 | 80-110 | ||||||||||||

| Y | 295-380 | ≥3 | 90-120 | ||||||||||||

| T | ≥350 | ≥110 | |||||||||||||

| TU3 | C1020 | C10200 |

|

0 | H00 | ≥195 | ≥195 | 200-275 | ≥30 | ≥20 | .. | ≤70 | .. | .. | |

| Y4 | 1/4H | H01 | 215-275 | 215-285 | 235-295 | ≥25 | ≥15 | 60-90 | 55-100 | ||||||

|

1/2H | H02 | 245-345 | 235-315 | 255-315 | ≥8 | ≥10 | 80-110 | 75-120 | ||||||

| H | H03 | ≥275 | 285-345 | 一 | ≥80 | ||||||||||

| Y | H04 | 295-380 | 295-360 | ≥3 | 90-120 | ||||||||||

| H06 | 325-385 | ||||||||||||||

|

H08 | ≥350 | 345-400 | .. | ≥110 | ||||||||||

| H10 | ≥360 | ||||||||||||||

| Remarks:Please contact us before hand if there are any special requirements on properties of products. | |||||||||||||||

Write your message here and send it to us