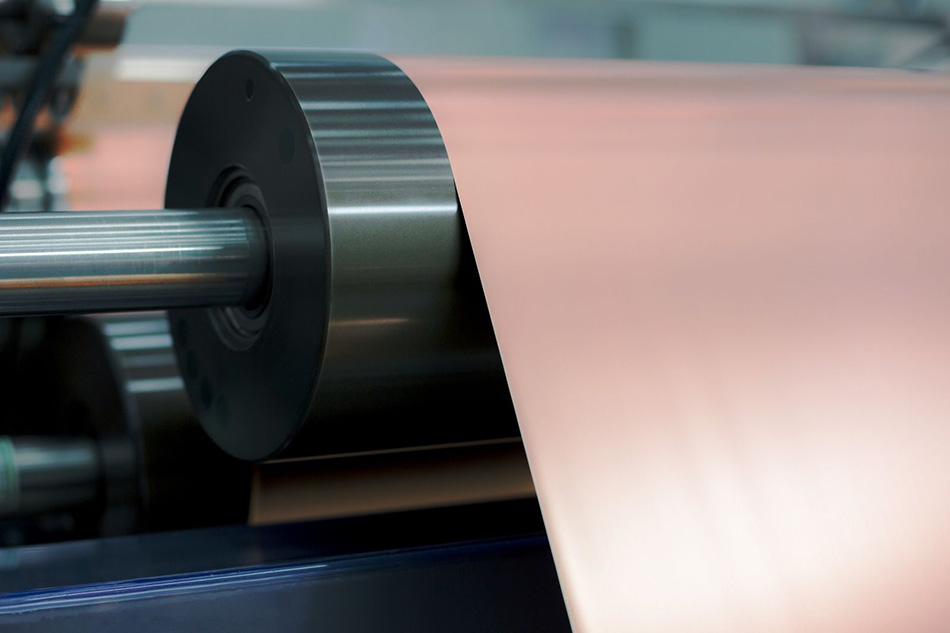

Very Low Profile Copper Foil (VLP-S-P/B)

Sub-micron micro-roughening treatment significantly increases surface area without affecting roughness, which is especially helpful for increasing adhesion strength. With high particle adhesion, there is no worry of particles falling off and contaminating lines. The Rzjis value after roughening is maintained at 1.0 µm and transparency of the film after being etched is also good.

● Thickness: 12um 18um 35um 50um 70um

● Standard Width: 1290mm, Width range:200-1340mm, can be cutting as per size request.

● Wooden box package

● ID:76 mm, 152 mm

● Length: Customized

● Sample can be supply

The treated foil is pink or black electrolytic copper foil of very low surface roughness. Compared with regular electrolytic copper foil, this VLP foil has finer crystals, which are equiaxed ones with flat ridges, have a surface roughness of 0.55μm, and have such merits as better size stability and higher hardness. This product is applicable to high-frequency and high-speed materials, mainly flexible circuit boards, high-frequency circuit boards, and ultra-fine circuit boards.

● Very Low profile

● High MIT

● Excellent etchability

● 2layer 3layer FPC

● EMI

● Fine circuit pattern

● Mobile phone Wireless charging

● High frequency board

|

Classification |

Unit |

Requirement |

Test Method |

|||||

|

Nominal thickness |

Um |

12 |

18 |

35 |

50 |

70 |

IPC-4562A |

|

|

Area Weight |

g/m² |

107±5 |

153±7 |

285± 10 |

435±15 |

585± 20 |

IPC-TM-650 2.2.12.2 |

|

|

Purity |

% |

≥99.8 |

IPC-TM-650 2.3.15 |

|||||

|

roughness |

Shiny side (Ra) |

սm |

≤0.43 |

IPC-TM-650 2.3.17 |

||||

|

Matte side(Rz) |

um |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

||

|

Tensile Strength |

R.T.(23°C) |

Mpa |

≥300 |

IPC-TM-650 2.4.18 |

||||

|

H.T.(180°C) |

≥180 |

|||||||

|

Elongation |

R.T.(23°C) |

% |

≥5 |

≥6 |

≥8 |

≥10 |

≥10 |

IPC-TM-650 2.4.18 |

|

H.T.(180°C |

≥6 |

≥6 |

≥6 |

≥6 |

≥6 |

|||

|

Peel Strength(FR-4) |

N/mm |

≥0.8 |

≥0.8 |

≥1.0 |

≥1.2 |

≥1.4 |

IPC-TM-650 2.4.8 |

|

|

lbs/in |

≥4.6 |

≥4.6 |

≥5.7 |

≥6.8 |

≥8.0 |

|||

| Pinholes & Porosity | Numbers |

No |

IPC-TM-650 2.1.2 |

|||||

| Anti-oxidization | R.T.(23°C) | Days |

180 |

|||||

| H.T.(200°C) |

Minutes |

30 |

/ |

|||||